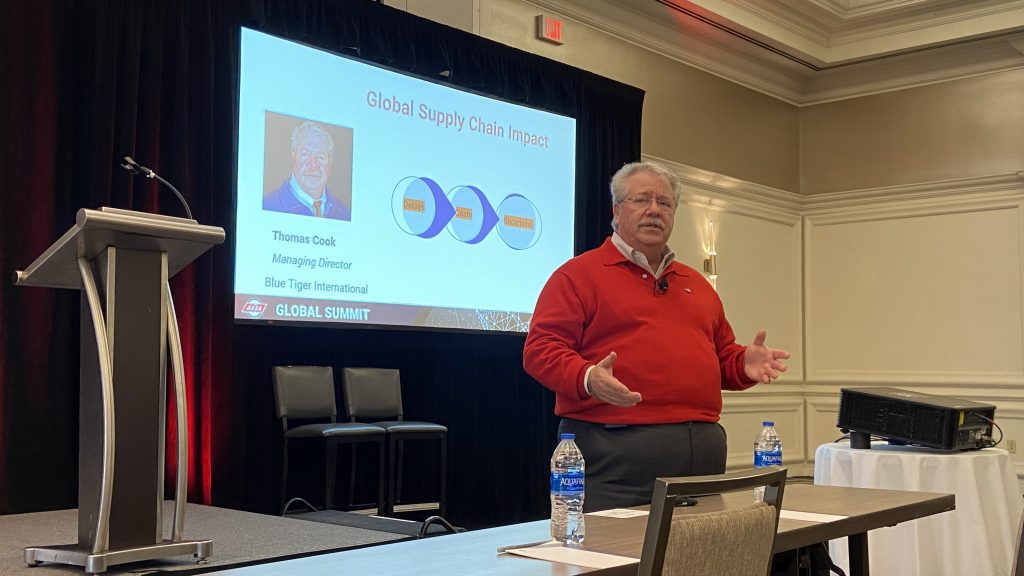

High demand for products and a lack of capacity for all of it continues to be a major driver of supply chain challenges, according to an expert.

Tom Cook, managing director at supply chain consultancy Blue Tiger International, told attendees of the 2022 Global Summit hosted by the Automotive Aftermarket Suppliers Association about a meeting he recently had with warehousing leaders. They told him 98 per cent of warehouse space in 80 per cent of major cities is fully occupied.

What these times have created is an imbalance of demand and capacity. After being caught by surprise by panic buyers, businesses are over-ordering products to ensure they have their shelves stocked. But that demand is overwhelming supply chains, reducing space availability and raising prices.

“So demand capacity is the big issue that we’re all dealing with. And the factor that demand is significantly greater than our capacities,” Cook explained in his presentation Global Supply Chain Impact.

Whether it’s a company based locally or in Ningbo, China, they’re anticipating their needs for raw materials, labour and manufacturing equipment based on historical data and anticipated demand. So when COVID-19 first hit, everything shut down. The only thing moving was personal protection equipment, Cook explained. Then when things started re-opening in the spring and summer of 2020, “you had a knee-jerk reaction by every person.

“It started with consumers and then [continued with] all the companies that do distribution and manufacturing. Everybody said, ‘I’m not going to be in this vulnerable position that I just was in the last three months.’ And that attitude and mindset continue today,” Cook said. “Everybody’s trying to fill up their inventories, whatever it may be, whatever they need.”

From the perspective of transportation companies and those that support the manufacturers, they’re struggling to keep up with demand. As with manufacturers, they base their plans — how many containers they need, the number of ships required, how many chassis are needed, the labour requirement — based on historical data.

But demand is now three times what was seen pre-COVID.

“So you have this demand and capacity which is imbalanced. That’s why we have the problems that we do in supply chain,” Cook said.

Leave a Reply