As the need to find more partners worldwide grows, Poland recently showcased its strength as a business partner for the Canadian automotive industry, including the aftermarket sector.

During a five-day tour with media from Canada, the United States and South Africa, the Polish Investment and Trade Agency, in partnership with the Ministry of Economic Development and Technology, introduced the Polish Automotive Group (PGM). The association is made up of 98 member companies that are not just family-owned businesses but also fully operate in the country. No branches or divisions of multinational corporations can be members.

PGM managing director Bartosz Mielecki shared that the automotive industry is the second biggest sector in the country (behind the food industry), employing more than 200,000 people directly (and about 350,000 indirectly). The auto parts sector is a USD$20 billion market — including a half-billion remanufacturing industry — and three-quarters of the products produced in Poland are shipped abroad.

From brakes to tires to batteries and more, Poland is the seventh largest parts exporter in the world, Mielecki said. With a diverse supply chain, he added that Poland can offer near-shoring benefits to North American automotive aftermarket companies.

Poland is also part of a larger hub of countries that work together, including Czechia, Slovakia, Hungary and Romania.

Mielecki noted that reliability, flexibility, engineering precision and competitive costs — offering European quality products at lower price points — are main attractions for working with Polish organizations.

One of those companies is Wuzetem, which manufactures diesel engine parts, mainly elements, nozzles and injectors, in Warsaw. Every stage of production takes place in Poland — nothing is outsourced. The company starts with the raw steel and oversees the entire production line in its near 110,000 sq-ft facility until the products are ready to be shipped — half of which goes to the North American market already. Its applications work for heavy duty equipment, passenger vehicles, trucks, agriculture and more. Almost one-fifth of its staff (50 of 270) work in research and development.

The tour showcased the detail, precision and expertise the company puts into its products. The company will be celebrating its 75th anniversary in 2026.

Research is a significant to the technological advancement among Polish companies. One such company was Pimot Lukasiewicz, an automotive research group that certifies technology in Europe. They test components like advanced driver assistance systems, high-voltage batteries and autonomous technology to ensure they’re safe to be used on roads.

Its facility has several buildings and testing fields where they put components and technology through rigorous testing.

Outside, the tour included getting up close with an autonomous testing vehicle, checking out the hardware used to power the testing, plus a look inside the vehicle, which included screens replicating what the vehicle sees. That includes thermal imaging to catch what a typical radar may not see on the side of the road.

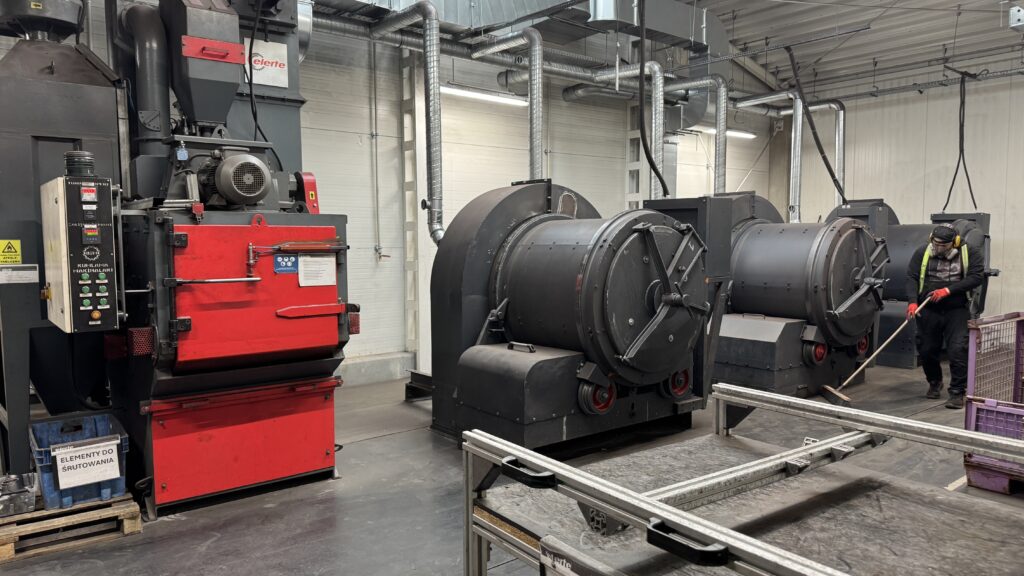

In Kielce, a city in south-central Poland, about 2.5 hours south of Warsaw, is Elerte. Its complex was originally a cottage – the building itself has been turned into offices and the area around it into a production hub that remanufactures 300 cores a day. These efforts of taking something that would have been tossed aside to be rebuilt and ready to sell are part of a growing remanufacturing movement in the automotive aftermarket.

With Elerte, export manager Marta Olk explained that they’re able to take their remanufactured product, sell at a lower price than brand new and offer a longer warranty than an original part — 25 months versus 12 months.

The company sources product from all over the world, with only about 5 per cent of cores received being damaged beyond the point of being remanufactured. But those that make the cut go through the full process at the facility, from breakdown to inspection to cleaning to rebuilding to powder coating to shipping out the door.

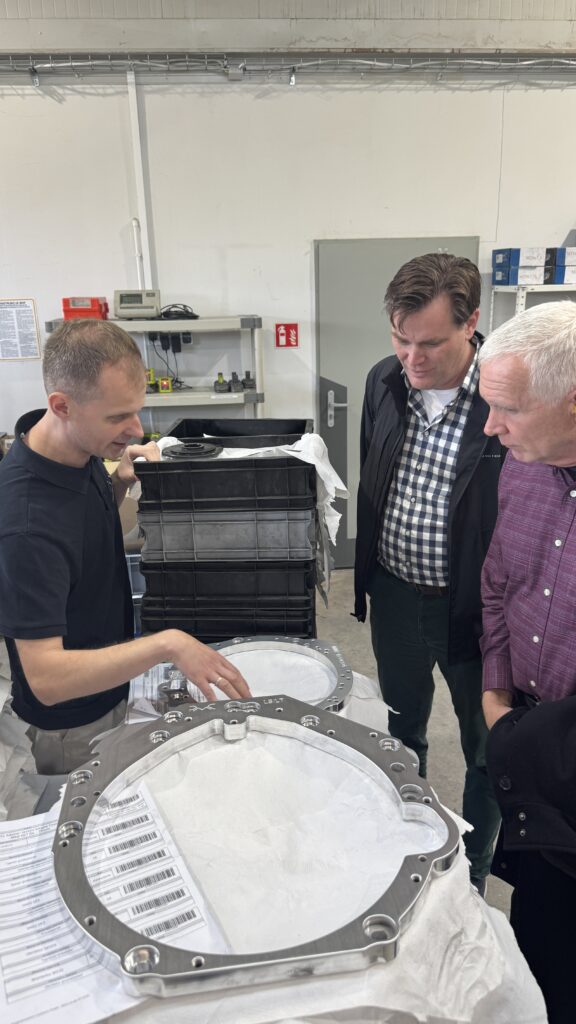

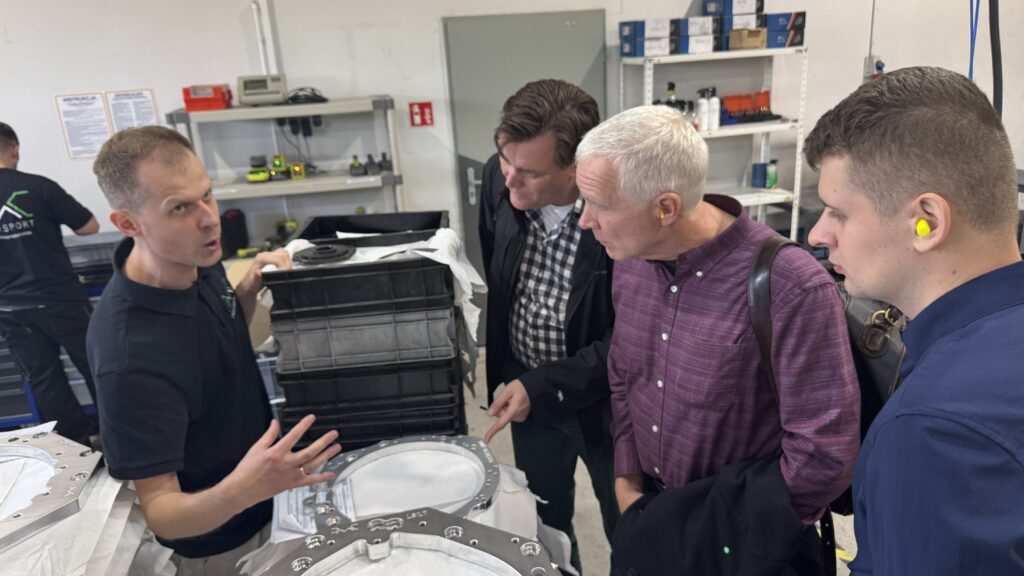

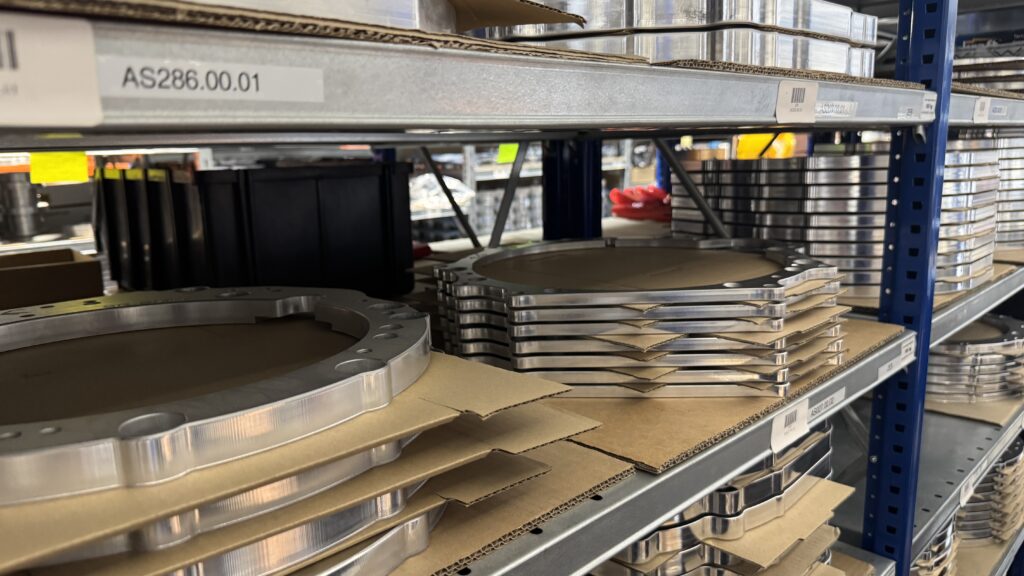

Also in Kielce is PMC Motorsport, which, as the name suggests, caters to the performance market. It has partnerships with shops that work with customers in the enthusiast and motorsport world. Here, customers can make custom orders — if a customer needs a specific part to adapt to an existing component or even replace the current one, the team will design it. Strength and precision are essential for the company to ensure durability and performance for the end user.

It also has an extensive catalogue of parts it has already created for customers over its 13 years. Engine swaps are the most common, but the company also has clutch kits, bearings, flywheels, gaskets, suspension kits, controller arms and braking components. So there is a good chance that a request may already have a fix and can be completed within two days.

Every step of the process, from design to completion, is done in-house.

And as vehicles advance in technology, Polish companies are working to create solutions.

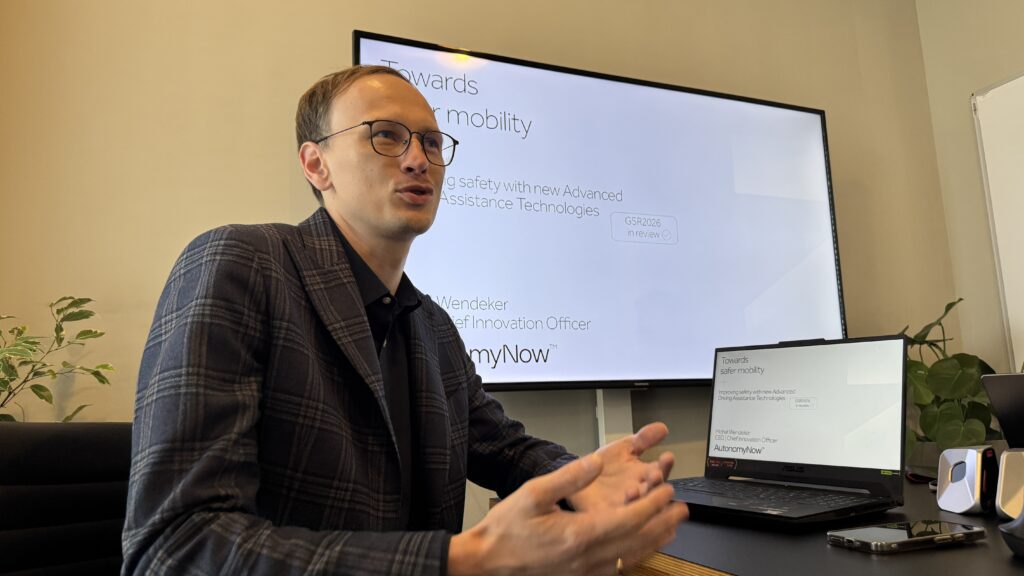

AutonomyNow in Lublin, southeast of Warsaw, is doing more than just coming up with an idea — it has developed and implemented autonomous solutions with a focus on the passenger and commercial bus space.

Michal Wendeker pointed out that in 2015, autonomous technology completed one trillion operations per second (TOPS). Today, it’s hitting 40 TOPS. And autonomous technology has allowed for a 52 per cent reduction in rear-end crashes. It also helps with driver monitoring, as 14 per cent of fatal crashes are caused by distracted driving.

What that shows, Wendeker pointed out, is that autonomous braking is the most important safety system. And it’s not about turning over all systems to an autonomous system, but helping alert drivers to the need to brake suddenly, speed changes or the fact that they may be distracted or drowsy behind the wheel.

Wendeker further noted that, since they cater to buses carrying large numbers of people, getting the technology right is critical. A false positive or an instance of sudden braking can create dangers for passengers.

Autonomous tech, at least at this stage, isn’t about eliminating drivers or full autonomy but assisting drivers and saving lives on our roads today. And it needs to be reliable or people with turn it off, Wendeker said.

Back in Waraw, the final PGM member visit was to the ITS, Motor Transport Institute. It’s a national association for certifications and regulation for things like products and environmental rules. Advanced vehicle technology is something they oversee closely.

It has the Connected and Autonomous Vehicles Competence Centre and DARTS, Database of Autonomous Vehicles Road Testing Scenarios. It collects data and road situations that are representative of road traffic in Poland and Central Europe. With the data collected, the centre creates simulations for autonomous technology to be tested in an in-house simulator.

The group especially likes to find difficult scenarios that drivers may encounter: If it’s hard for a human, then they want to test vehicles in those situations. And it wants to gather real data on how people really drive — not everyone obeys the law, so they plan and test in situations representative of that.

There is also a focus on transportation psychology — gaining insight of how drivers think when they drive. Furthermore, the group noted that there’s a gap in education with respect to how to drive with autonomous vehicles and understanding how they work and how to either be a passenger on them or be a driver around them.

The centre has a pair of simulators, one for trucks and another for passenger vehicles. At the control desk, the administrator of the test can pull up different scenarios from country driving to city driving to highway driving and have the person in the simulator drive as if they’re on those roads. This gives the centre insights to how real drivers would react and behave in such conditions.

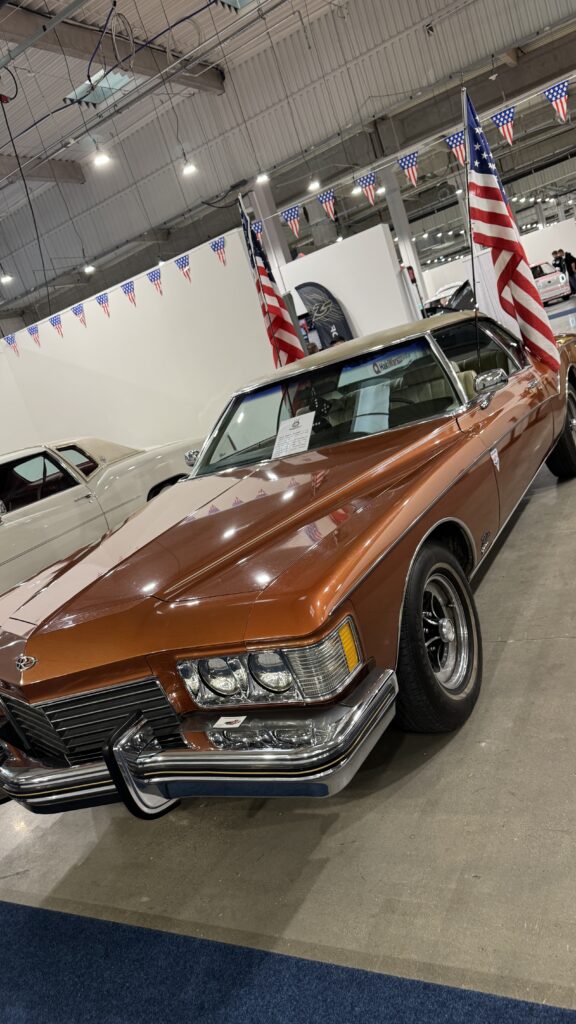

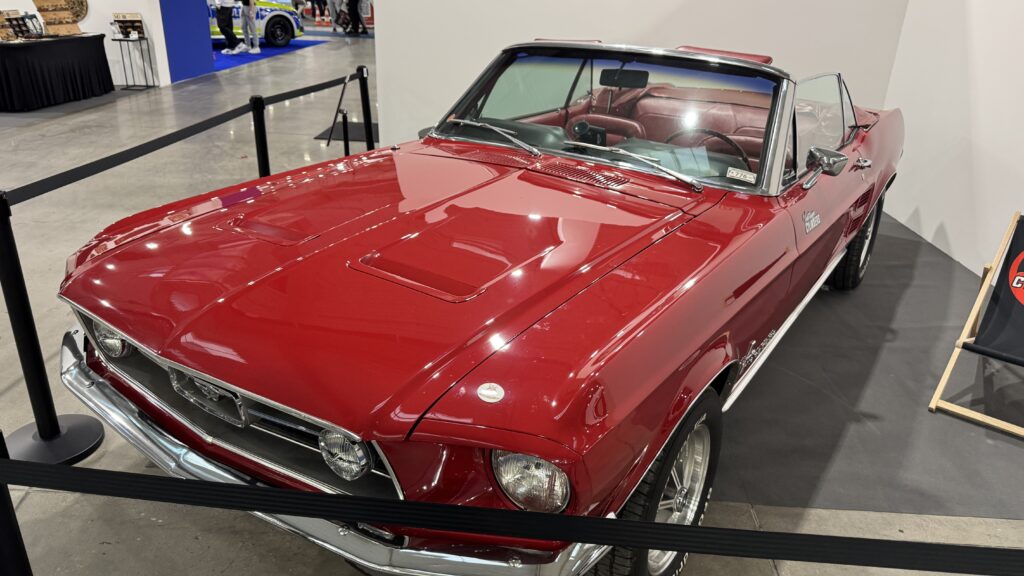

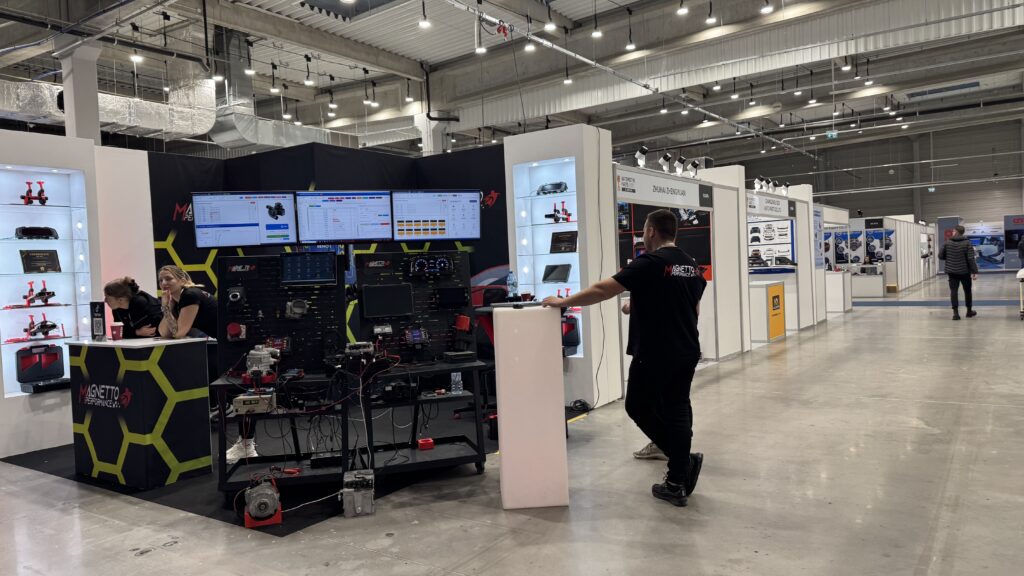

The final stop was the Warsaw Motor Show, which included classic and new vehicles, plus the Automotive Parts Expo, which was a similar experience of AAPEX in Las Vegas, where attendees could check out vendor booths and displays for parts and components.

Check out our full photo gallery below and highlight reels above.

Leave a Reply