Smooth Moves

Share

Share

Have you ever taken a hard look at scrapped vehicles at your local automotive recycler? Dave Cerveny, senior technical trainer for Affinia Global Chassis has and he says that too often the vehicles still have the original factory struts. “It’s an out of sight out of mind sort of thing, but those struts should have been replaced many kilometres ago.” In fact, most OE specifications recommend that shocks and struts should be replaced after 80,000 km.

Since most vehicles have two to three owners throughout their lifespan, it’s astounding how many end up at a recycler with original parts. In terms of shocks and struts, after 80,000 km the first stage valving has moved about 75 million times and it starts to fatigue.

The key to harnessing the missed opportunities in selling ride control replacement parts is through educating the customer.

Many vehicle owners don’t understand that shocks and struts wear over time. The symptoms are subtle and unfortunately drivers just get used to a bumpy ride. What technicians need to educate their customers on is that it’s much more than having a smooth ride — worn shocks and struts create a huge safety issue with the steering and braking systems and tires.

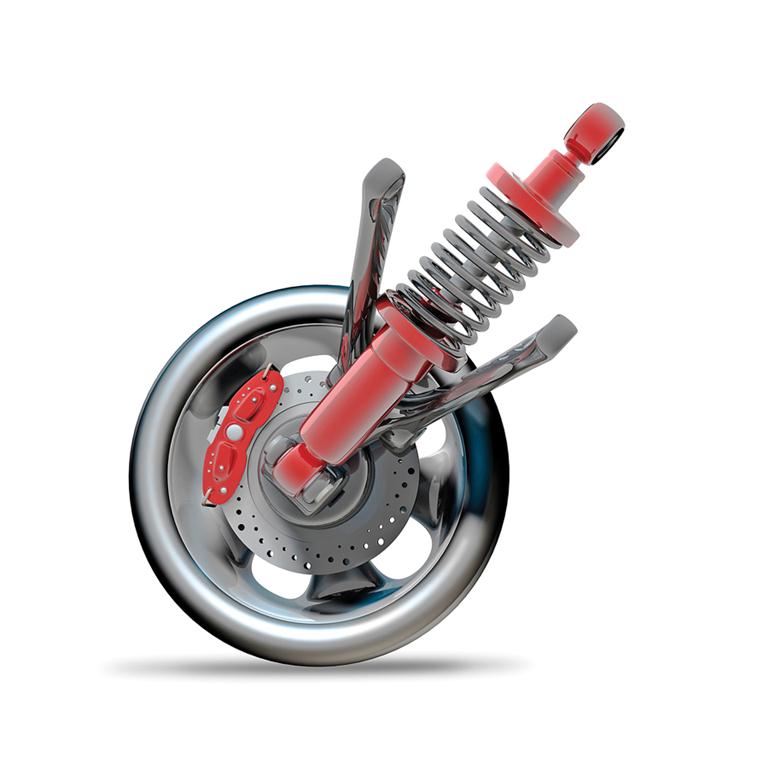

“Brake efficiency can be reduced by as much as 23 per cent with half worn shocks or struts,” says Mac McGovern, director of marketing and training for KYB Americas Corp. “If the body is unstable all of those systems are affected. The shocks and struts are the glue that keep them all working.”

To diagnose ride control or other suspension issues, Cerveny says, “Go back to basics. I can’t stress enough the importance of inspecting a vehicle in its natural state, meaning on the ground or on a drive rack. A lot of techs would have the vehicle up in the air. All of the suspension parts would be hanging down, creating stress and changing the geometry.”

A simple road test can be conducted in the service station parking lot. KYB offers a system called “Stop, Squat and Roll” to help techs identify ride control issues.

For example, driving at a speed of seven or eight kilometres, make an abrupt stop. If the vehicle shows signs of brake dive — front end goes down as the back end rises — it means that the shocks and struts are allowing excessive weight transfer from the rear to the front of the vehicle.

Monroe Shocks and Struts, manufactured by Tenneco, offers a similar test drive check list called the Safety Triangle — steering, stopping and stability. “Brake dive is one of the reasons why worn shocks and struts can increase a vehicle’s stopping distance,” says Bill Dennie, director of ride control channel management for Monroe. “If the front end lifts when accelerating from a stop, it’s called acceleration squat and is also a sign of excessive weight transfer.”

To check the overall vehicle stability, McGovern suggests moving the steering wheel from left to right and back to center quickly. This will show how responsive the steering is and if there is too much body roll.

Documenting each inspection will also help the service manager or technician better communicate issues or potential issues to the customer to help them make an informed decision. “If you explain it all to the customer and they say, ‘You’re crazy’ or ‘I don’t have the money for that repair,’ what do you think happens on their drive home?” says McGovern. “Now that they are aware of it and sensitized to it, they’ll notice it. When information is given to the customer properly the percentage of capturing the sale is far greater on the return visit.”

Certainly, if there were a mechanical or suspension issue with a vehicle 20 years ago, the driver would definitely notice. However, today’s vehicles employ an array of high tech sensors and computer controls, which dampen the once obvious symptoms of component failure — vehicles coming off the assembly line now feature innovative technologies such as steering wheel angle sensors for drift compensation. What’s rolling into service station bays today, are those vehicles that were built after 2000 with electronic stability control (ESC), anti-lock braking systems (ABS) and traction control. With such systems it’s essential that technicians choose the right replacement parts to keep the vehicle operating within the OE design parameters.

“When choosing shocks or struts, it makes no sense to select a product that’s not capable of doing what the vehicle is designed to do. The sensors in the vehicle allow the system to understand when a vehicle is losing control. It will apply the brakes individually, slow the engine speed, etc. to regain control [for the driver],” explains McGovern. “If you put behaviour changing components on the vehicle, the system is going to work differently and it will be harder for it to maintain control of the vehicle.”

One installer told KYB that he had replaced struts on a vehicle but didn’t install the right ones because they weren’t available at the time of repair, so he just got ones that would fit.

“The customer discovered that while rounding curves at highway speeds the cruise control would disengage. The onboard electronics in the vehicle knows when you’ve put on incorrect or substandard components and the motor suffers as a result,” says McGovern.

Indeed, choosing a ride control replacement part that meets the vehicle’s design specifications is vital not only for the passenger’s safety but also to increase the longevity of the vehicle. Loaded struts and complete assemblies are the hottest items on the market today and aftermarket suppliers offer a variety of products for full coverage of domestic and foreign nameplates. The benefit of using a complete assembly is two-fold – installation times are shorter and the customer gets all new parts.

McGovern says that about 85 per cent of vehicles today have twin tube shock or strut designs. The most common KYB OE replacement shock or strut is its GR-2/Excel-G twin tube design.

Monroe’s OESpectrum line features a Twin Technology Active Control system that, according to Dennie, is engineered specifically to filter out noise, vibration and harshness (NVH), which are common issues in passenger vehicles with lighter-weight suspension system and low-profile tires. “Drivers love that fingertip control but wish they had something to reduce the related NVH,” says Dennie.

But keep in mind, even if the right part is installed, component failure can affect many other aspects of the vehicle’s performance.

Much like the song Dem Bones — the leg bone’s connected to the knee bone — if issues with the shocks or struts are identified, Cerveny advises techs to check the suspension system, steering, brakes and tires. “If the shocks or struts are worn, that could be destroying the tires. If there’s a problem with the steering and suspension, you should be checking the brakes. A piston rod on the strut can be bent if the car bounces off a curb. Stabilizer legs can get worn out, creating body roll. And even the bushings can become mushy, having a huge affect on the handling of the vehicle. A good technician will check all components in the vehicle.”

The most important element for the safety of drivers on the road today is keeping the tires on the road. By understanding the relationship between steering, braking and tires, a

nd what it takes to keep them all within the OE designed parameters will increase vehicle safety while helping technicians land more ride control sales.

Plus, having the ability to properly inform customers of the importance of such repairs, McGovern says, “it’s no longer a matter of opinion or cost, it’s a matter of fact.”

Leave a Reply