What is extrusion molding? Shaping vehicle and industrial components

Share

Share

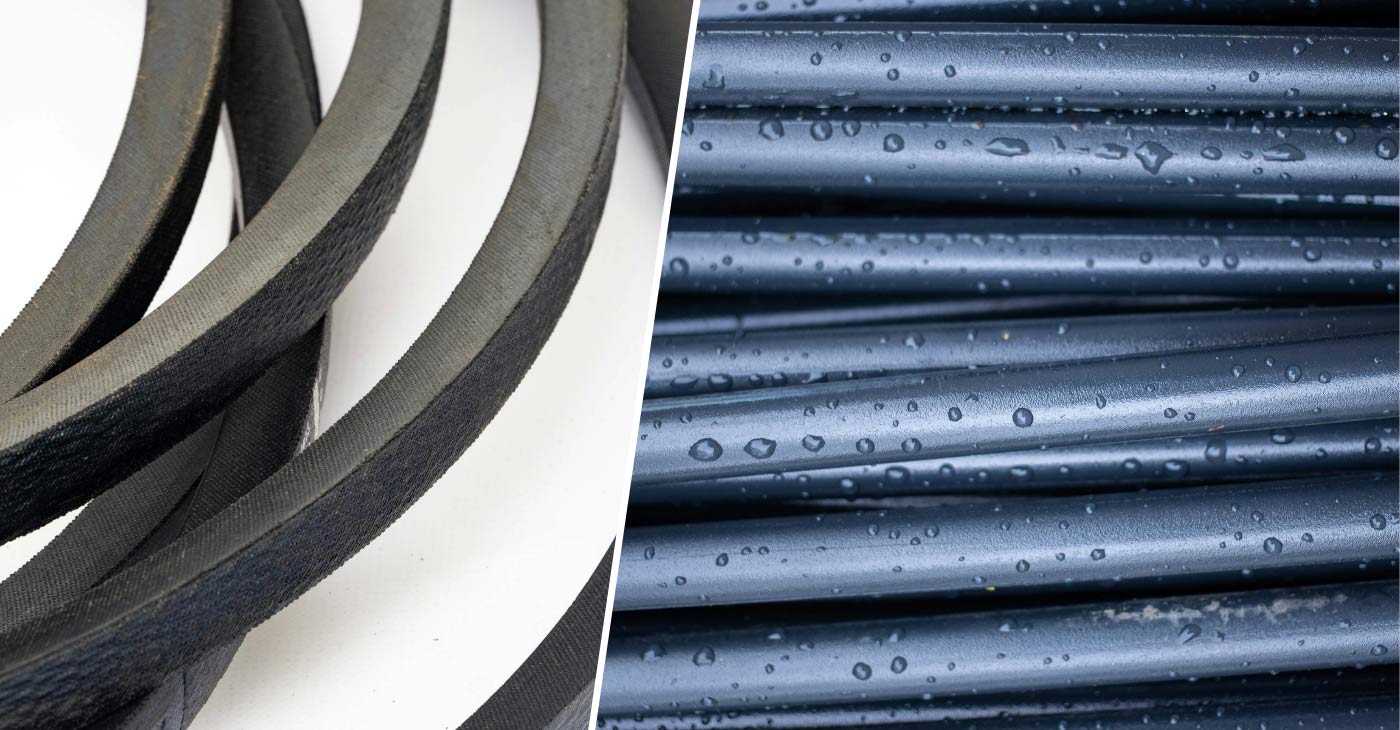

Have you ever wondered how everyday components in vehicles and industrial machinery are manufactured with such precision? One process lies at the heart of this production: extrusion molding. From durable hoses to intricate sealing systems, this process plays a critical role in shaping the world of automotive and industrial parts.

Before these components are molded, the raw materials—especially rubber—need to be sourced and processed. Natural rubber, for instance, is derived from latex harvested from rubber trees (Hevea brasiliensis). This latex is collected by tapping the trees, then processed through coagulation and refining to produce raw rubber. Known for its excellent elasticity and resilience, this rubber is then prepared for further processing, such as extrusion molding, where it can be shaped into vehicle seals, hoses, and other critical components.

Let’s dive into how extrusion molding powers innovation in these sectors, crafting essential components like weather seals, fuel lines, and electrical cable insulators that keep our cars and machinery running smoothly.

So what is extrusion molding actually? Extrusion molding is a continuous manufacturing process that forces softened material through a precision-engineered die, creating components with a uniform cross-section. In the automotive and heavy-duty machinery industries, extrusion molding is akin to squeezing molten material through a die to produce complex profiles such as bumper reinforcements, hydraulic hoses, or engine gaskets.

Think of it as a refined system similar to squeezing grease from a cartridge, only on an industrial scale, where precision is key. Unlike injection molding, where materials are injected into a closed mold, extrusion molding produces continuous lengths of material – ideal for producing wiring harness insulation, tubing, and frame profiles.

The core of this process lies in the die, a custom-designed metal tool that defines the shape of the extruded part. This is particularly important in the automotive industry, where exact tolerances are crucial for components like rubber gaskets, which ensure waterproofing in vehicle doors, or elastomeric seals, which must withstand both temperature extremes and mechanical stresses in heavy machinery.

Here’s how extrusion molding works in detail, focusing on how the process applies to automotive and industrial components:

By controlling every step, extrusion molding ensures the production of consistent and reliable components, meeting the stringent requirements of the automotive and machinery sectors.

Extrusion molding is indispensable in the production of various automotive and industrial components. Some of the most critical applications include:

Why is extrusion molding so vital in these industries? Here are the key benefits:

This process is ideal for producing long, continuous profiles like cables, seals, and tubes in high volumes. Automotive manufacturers benefit from this scalability, allowing them to produce components in vast quantities at a lower cost.

Extrusion molding can handle a wide range of materials, including high-performance rubbers, thermoplastics, and even lightweight metals like aluminum. This flexibility makes it possible to produce components with specific properties like chemical resistance, heat tolerance, and mechanical strength.

While the continuous extrusion process is ideal for parts with uniform cross-sections, advanced die design allows for complex shapes. This is crucial for producing multi-functional automotive components like multi-chambered weather seals or integrated bumpers.

While extrusion molding has many advantages, using it also faces its challenges, especially in automotive and industrial applications:

Complex designs – While extrusion is ideal for producing continuous shapes, highly complex designs with detailed features might require additional finishing processes. For instance, parts with intricate geometries might be better suited to injection molding.

Material waste during setup – Transitioning between different products may result in material wastage, particularly when adjusting dies for varying profiles. This can be a concern when switching from one vehicle part to another with different specifications.

Material constraints – Certain materials may not be suitable for extrusion molding, particularly those that don’t flow easily when heated. While most rubbers and plastics used in automotive applications are ideal, more rigid or brittle materials may pose challenges.

Extrusion molding is vast and dynamic. This only scratches the surface! How do everyday things work? This molding influences the world in multiple ways. In essence, what is extrusion molding? Living or working in a field that uses this intriguing method may have shown it.

Here are some resources:

https://www.4spe.org/

https://www.americanchemistry.com/chemistry-in-america/news-trends/blog-post/2022/the-story-of-plastics-and-acc

https://www.compositesworld.com/topics/application

Extrusion molding has transformed the way automotive and industrial components are manufactured. Its efficiency, scalability, and material flexibility make it an indispensable process for producing everything from rubber seals to fuel lines and protective bumpers.

As the automotive and machinery industries continue to evolve, particularly with the rise of electric vehicles and high-performance machinery, extrusion molding will remain at the forefront, enabling manufacturers to push the boundaries of component design and material performance.

Whether it’s the gasket ensuring your engine remains leak-free or the cables powering your hybrid car, extrusion molding is shaping the future of vehicle and machinery production.

Leave a Reply