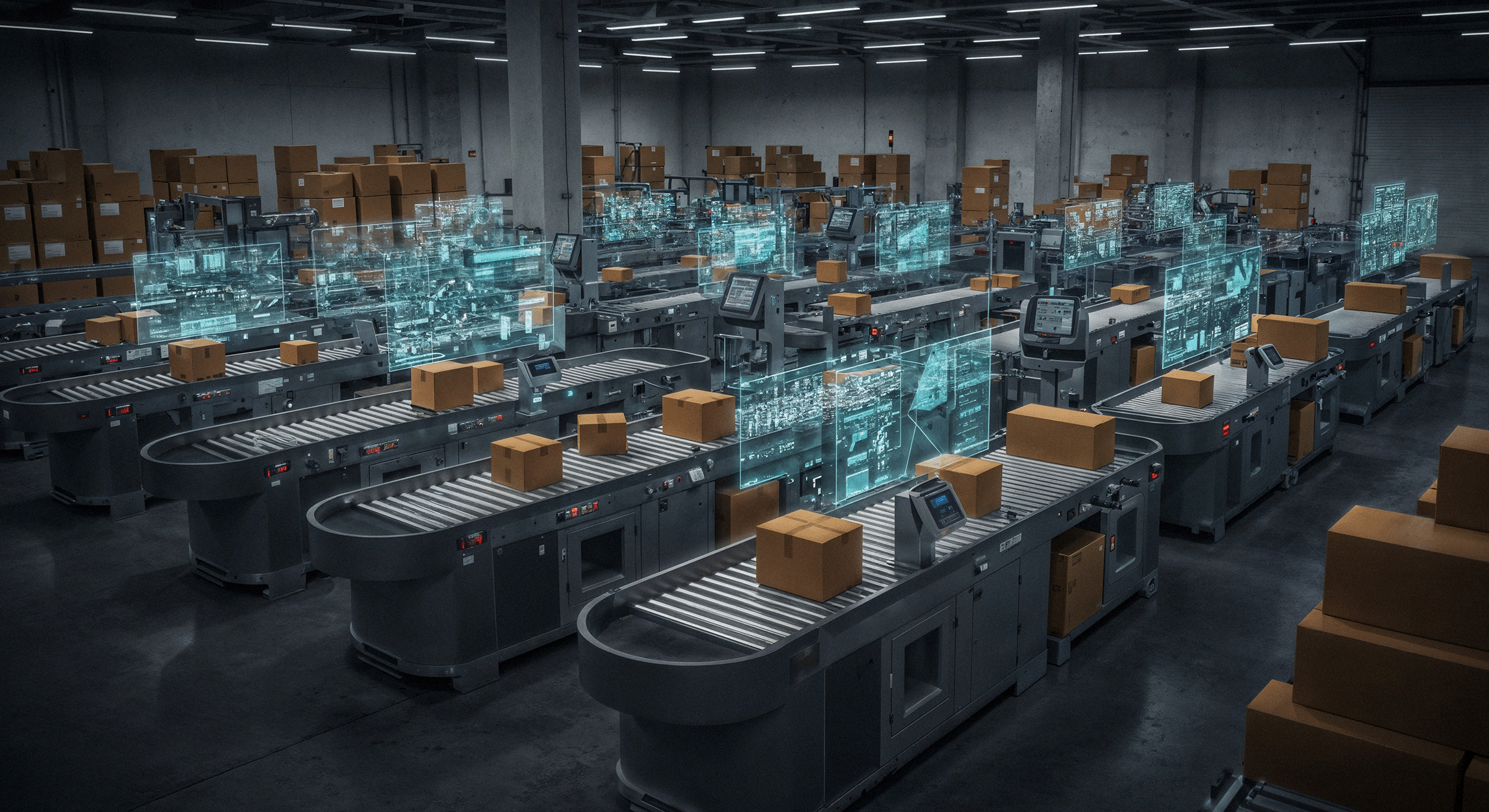

How AI and new technologies are transforming warehouse operations and the overall logistics sector

In an industry built on precision, timing and availability, the success of the automotive aftermarket relies on the strength of its supply chain. From retail outlets to distributors, every link in the warehouse operations chain affects how quickly and efficiently customers get what they need.

And in 2025, that chain is being pulled in new directions.

Warehouses are no longer just storage spaces — they’re becoming high-tech hubs powered by drones, robotics and artificial intelligence. These technologies are slashing labour costs, boosting inventory accuracy and giving shop owners and distributors real-time visibility into their operations. At the same time, procurement is undergoing a quiet revolution, with AI agents now capable of negotiating contracts, generating market reports and even managing entire sourcing workflows.

But it’s not just about automation. The global landscape is shifting, too. Geopolitical tensions, emerging uncertainty and rising regulatory pressures are forcing businesses to rethink how and where they source materials. For the auto care industry, that means building more resilient, flexible supply networks that can weather disruption — whether it’s a port strike, economic uncertainty or a policy change.

This year’s trends point to a future where supply chains are smarter, faster and more autonomous. But they also demand a new kind of leadership — one that blends technology with strategy and innovation with adaptability. For aftermarket professionals, staying ahead means embracing these changes, not just reacting to them.

Marrying robotics and technology

Robotics and technology go hand in hand, but if they don’t work in unison, warehouse operations are likely to encounter setbacks.

As Jim Hoefflin, CEO of Softeon, told an audience at Manifest 2025, there’s still a great deal of variation in how robotics and technology are deployed in warehouse environments.

“It’s like first-generation WMS [warehouse management systems], and they’re just starting,” he said. “They’re good at how they create their workflow. They bring you different automation substances. I think the key to all of it is how you set that up.”

Hoefflin said his company dedicates significant time to warehouse execution and communication, helping customers adapt and offering ongoing support.

“Automation products are changing by the week or month. You can’t buy something and sit around for any amount of time,” he said.

Josip Cesic, CEO of Gideon, said that in his company’s operations —which involve loading and unloading truck trailers across multiple industries — robotics must be flexible and capable of making decisions in real time.

“These days, with all the investments in AI and computing, robots are really able to solve those moving problems,” he said.

Although typically separate from electronic processes inside a facility, Cesic said loading bays offer a good starting point for automation.

“There are a number of technologies that can enable or help optimize processes across a facility, but the loading bay is relatively separated,” he said. “So from an adoption perspective, it’s a really great use case to start and learn about automation and take the journey forward.”

Corvus Robotics develops inventory drones that fly autonomously and scan pallet labels to enable fully automated inventory tracking.

Jackie Wu, CEO and co-founder of Corvus Robotics, said the ability to deploy quickly in varied environments depends on strong integration with existing technology.

“Some of the core technologies that are mature allow us to set up these drones,” said Wu.

Hoefflin said he encourages customers to focus on delivering faster, higher-value solutions to elevate productivity.

“All of this automation is really good at upsetting what was the industry norm, and we’re in a better position today,” he said.

“All of this automation is really good at upsetting what was the industry norm, and we’re in a better position today.”

Drones transform warehouse operations

Warehouses are increasingly adopting automation as companies look for new ways to reduce costs, improve accuracy and ease the physical burden on workers. The emergence of drones is making an impact.

At the NextGen Supply Chain Conference in Chicago late last year, AJ Raaker, director of warehouse development with Taylor Logistics, discussed how drones can enhance inventory accuracy and efficiency — especially when paired with artificial intelligence tools like vision-based systems, which deliver richer data than traditional barcodes.

“Here’s what it looks like: A commercially off-the-shelf drone flies itself, takes images of inventory locations and converts those into data like case counts, occupancy levels and inventory matches,” said Raaker.

Drones boost efficiency by collecting billions of data points weekly, providing insights into inventory status, damage and location. These benefits extend to customer visibility, SLA accuracy and labour savings.

“In a facility with about 20,000 rack locations, we were able to cut about 87 per cent of the labour required for inventory management, giving time back to other programs,” said Raaker.

Gather AI supplies warehouse drones for inventory management, helping businesses save money, reduce losses and improve both productivity and revenue. Their setup includes mapping rack locations using QR codes, integrating with the WMS and training staff on how to use the technology.

The drones operate autonomously and don’t rely on Wi-Fi, making them easier to scale.

Raaker said early iterations of the AI struggled with specific tasks, like counting bags of dog food. But machine learning and ongoing data collection steadily improved accuracy.

“But as we collected more data, our learning got better,” he said.

Taylor Logistics ultimately achieved better inventory accuracy, cost savings and higher customer satisfaction.

“Our customers can virtually walk through the warehouse from anywhere in the world,” said Raaker. “This is AI having a real, tangible impact on supply chains — improving inventory accuracy while reducing labour.”

“AI will continue to be one of the most transformative forces in supply chain management next year and beyond, driving advancements across three key areas: Productivity, process and product.”

AI helps transform procurement

Artificial intelligence (AI) is transforming the supply chain sector — and procurement is no exception.

Ryan Polk, senior director analyst with Gartner, outlined three megatrends shaping procurement. As AI adoption accelerates, he said the real challenge lies not in the technology, but in the people managing it.

“The challenge isn’t the tech — it’s the people,” said Polk. “We’re trying to run AI initiatives like IT projects, but they require a total operating model shift.”

Agentic AI models can expand operational context, apply reasoning and integrate multiple types of information to communicate, process or understand tasks.

“Yesterday’s models were largely trained on the accuracy of their output,” said Polk. “Today’s models are being trained on how they reason their way to that output in the first place.”

Thanks to these capabilities, AI agents can begin automating routine procurement tasks.

“When we say an agent, what I’m referring to is an AI model that has the ability to, one, perceive an environment, and two, act on that environment, independent of a human,” said Polk. “There are agents that can help with negotiating supplier contracts. There are other agents that are coming online that can help prepare market research reports based on publicly available information and provide those back to category managers and sourcing managers.”

Polk added that multiagent systems are on the way, with the potential to automate entire procurement processes.

A human user provides a prompt. An orchestrator agent sends the request to sourcing, negotiations and contracts agents. Once processed, a human reviews the output before a compliance agent deploys the results.

While there’s ongoing concern about AI replacing humans, Polk stressed the need for collaboration between the two.

AI can handle repeatable tasks, but humans will still be needed for edge cases and exceptions — frequent challenges in supply chains.

“There’s typically data somewhere within the organization that describes how we go from point A to point B,” said Polk. “It usually exists in policies and procedures. We believe that agents are going to be best suited to support and take over, or at least augment in some way, shape or form, that work because there’s data somewhere within the organization that we can use to train AI models.

“But there’s another portion of work that we all do as well — non-standard, atypical work that doesn’t follow established rules or procedures.”

As AI takes on more standardized tasks, procurement skillsets will evolve. Human-AI collaboration, data literacy, prompt engineering, inductive analysis and strategic thinking will become increasingly important. Skills like negotiation and data visualization may decline in demand.

Uncertainty

Polk also pointed to rising global regulations as a significant factor reshaping procurement.

“There are new regulations popping up in different locations related to better risk management, more protectionism, more sustainability and more consumer protection,” he said. “We’re seeing the sheer volume of regulations really challenge what we all do — challenge us to comply in different ways.”

He added that although countries may regulate similar issues — like data privacy or digital sovereignty — they often do so in different ways, complicating compliance.

And then there’s the impact of growing protectionist trade policies.

To respond to geopolitical instability, Polk said businesses should evaluate four strategic options:

■ Divesting: Relocating procurement operations;

■ Decoupling: Building separate, independent ecosystems;

■ Diversifying: Adding new suppliers outside existing regions;

■ Doubling down: Expanding current supplier networks for resilience.

But there are other uncertainties on the rise as well, such as energy uncertainty. Polk warned that demand — driven by AI data centres, population growth and economic expansion — may lead to electricity rationing in countries like the U.S., India, Australia, Brazil and potentially Canada.

“If the current trajectory holds true, what we’re likely to start seeing is more and more electricity rationing,” he said. “We need to think about our energy strategies much more strategically than we are today.”

As energy becomes more decentralized, digitized and decarbonized, he said companies must treat it as a critical spend category and build strong partnerships in the space.

“If there’s one thing 2024 taught us, it’s that supply chain disruptions will occur, and preparing for them seems to be an obvious step for suppliers to take in 2025 to stay ahead of the curve.”

This year’s trends

Looking at 2025, AI is set to remain a powerful force in the supply chain world. Whether it’s optimizing warehouses, enhancing inventory management, improving transportation, increasing productivity or building resilience, those who use the technology wisely will reap the benefits.

“AI will continue to be one of the most transformative forces in supply chain management next year and beyond, driving advancements across three key areas: Productivity, process and product,” said Paul Magel, president of the business applications and technology outsourcing division at Computer Generated Solutions and its BlueCherry team.

Magel said AI will boost productivity through better daily operations and decision-making. On the product side, he expects AI to become central to many tech platforms, enabling smarter automation.

“AI will evolve to a point where systems can operate independently — analyzing data, solving problems and taking action without user input, leading to a more seamless and self-sufficient supply chain,” he said.

AI will also help mitigate global disruptions like the Canadian rail and U.S. East Coast port strikes.

“Looking ahead to 2025, supply chain teams will increase their investments in AI solutions across the end-to-end supply chain, focusing particularly on improving predictive analytics and scenario planning capabilities to enhance resilience and agility,” said Jeff Trino, supply chain leader at Genpact.

“While both the Canadian rail and U.S. port strikes were resolved fairly quickly, they left suppliers scrambling to reroute products. If there’s one thing 2024 taught us, it’s that supply chain disruptions will occur, and preparing for them seems to be an obvious step for suppliers to take in 2025 to stay ahead of the curve.”

And AI will continue to revolutionize order management as well.

“Traditionally, the order management process has been time- and labour-intensive. It can take hours for a human to triage a new request, interpret and classify it, match it with data and triage it before sending it to the client,” said Trino. “Now, AI agent models can auto-classify client requests, remember prior interactions and generate recommendations for the next best action, which are quickly reviewed by team members for accuracy. That’s hours of saved time across the team, allowing them to focus on more strategic, customer-facing activities.”

Better analytics will also drive smarter decision-making.

“Access to real-time visibility and predictive analytics relies on quality data and smart data management practices,” said Trino. “AI can help enrich data catalogues, cleanse data sets and detect anomalies. Organizations with AI embedded throughout the supply chain — across planning, sourcing, making, delivering and aftersales functions — can respond to disruptions more quickly and make data-backed decisions to redirect goods and inventory.”

Improved forecasting, driven by AI, will allow companies to optimize stocking levels based on historical behaviour, market trends and macroeconomic signals.

“As the predictive capabilities of AI models improve, the target level of inventory to be produced and stocked can be adjusted to maximize profitability,” said Trino.

AI in warehouses

Warehouse operations continue to be among the top adopters of AI and robotics. Bill Stenger, head of sales for the Americas at Swisslog, said adaptable technologies that use data to improve efficiency are leading the way.

“Collaborative robotics will play a key role in adapting to labour availability and productivity challenges,” said Stenger. “These technologies will allow operations to run longer, helping meet customers’ expectations for service levels.”

He also pointed to AI’s importance in addressing the labour shortage.

“You don’t have employees with 10, 15 or 20 years of experience who know the ins and outs of operations,” he said. “We need to empower employees who will be with us for one, three or five years with data and decision-making tools. AI will play a crucial role in providing suggestions to operators, helping them make smarter decisions and boosting their confidence.”

This article originally appeared in the July issue of Jobber News

Leave a Reply