New-generation Minis and future BMWs with front-wheel drive will all use automatic transmissions from Aisin AW, according to a leading engineer from the German luxury car manufacturer. Presenting a paper on BMW’s latest powertrain strategy at the CTI Symposium on Advanced Transmissions and Hybrid Drives in Berlin last month, Dr. Robert Meyer, the group’s head of automatic transmissions, said that the new generation of three- and four-cylinder modular turbocharged engines would require a parallel new generation of gearboxes aligned to the performance characteristics of the new power plants.

While all Mini models are front- or all-wheel drive, BMW’s range of sedans, wagons and sports cars are all rear driven and its SUVs and some of its other passenger cars have the option of all-wheel drive. In the near future, however, BMW will launch its first passenger cars with front-wheel drive. These will be mid-sized models and will share a new chassis architecture with the latest models in the Mini family. It is these models, said Meyer,that will use planetary automatic transmissions from Aisin AW. Initially, the Mini gearboxes will be six-speed, but a Mini with the new eight-speed derivative of the Aisin transmission is “perfectly possible.”

Asked whether BMW had considered a dual clutch gearbox as a transmission option for the new platform, Meyer said the company “had not rejected DCT for our front-drive applications.” However, he added that the shift dynamics of a planetary gearbox could now be just as good as those of a DCT, and that there were “a couple of other factors” swinging the decision in favor of the Aisin system. One of those factors could be the fact that the outgoing generation of Minis is already employing the second-generation Aisin unit; even so, many commentators will find it surprising that BMW has not chosen to go with the highly advanced nine-speed 9HP from its regular transmission supplier ZF.

Third Generation: Improved Efficiency

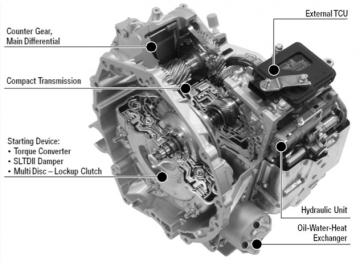

As well as the obvious constraints of tight packaging for the transverse front-wheel drive platform, the new transmission would have to deliver significant additional benefits over existing designs, said Meyer. On the checklist were major gains in efficiency in order to meet tightening CO2 and emissions standards worldwide. The all-turbo gasoline and diesel engine line-up dictated narrow steps between gears, and the presence of three-cylinder units in the range meant extremely effective vibration damping would be required if the down-speeded engine operation essential to good CO2 performance were to be achieved with a high level of driving refinement.

“A major challenge was to meet the requirement to significantly improve the damping capability of the torque converter,” said Meyer. “The application of turbocharged engines with increased low end torque combined with transmissions topologies with increased spread, allow for operation at very low speeds. This helps to optimize fuel consumption, but also significantly increases the level of torque fluctuations. To cope with these conditions, a newly developed super long travel damping system is being applied.”

In addition, the new transmission, with its three planetary gear sets, is compatible with stop-start operation. It also incorporates a decoupling mechanism when the vehicle is at rest with the engine running, further reducing parasitic drag. The overall improvement in fuel efficiency in the BMW application is an impressive 14% for the six-speed, with 2% attributable to down-speeding and 1% to the ability to lock up the torque converter as low as 1100 rpm. 2 to 3 percent is saved through the optimized decoupling, and 8 to 10 % through gains in hardware efficiency. These figures do not include the benefits of the stop-start system or the transmission’s ability to coast on the overrun, says Meyer.

Speaking at the same conference, Aisin AW’s general manager of product engineering, Tomohiro Kobayashi, explained that the gains were made through a combination of drag loss reduction, an expanded range where lock-up could be applied, and through the wider ratio spread. Six-speed editions of the transmissions have a spread of up to 6.64, while the eight-speed built on the same architecture widens the spread to 7.80 to provide ratios 16% higher as well as 8% lower than the previous generation six-speed unit.

CFD analysis and ATF flow visualization had allowed engineers to optimize the friction material design to achieve a remarkable 77% reduction in clutch and brake drag torque, added Kobayashi, contributing to the overall fuel efficiency gain of 14% for the six-speed and 16.5% for the eight-speed version. Yet, impressive though these results are, there is more to come:

“We are already working on the next generation of FWD transmissions,” says Kobayashi. “We aren’t just improving them – we are re-inventing them. This is not just progress, but a great leap forward – so look forward to our new design in the near future.”

Leave a Reply