Designers of Cadillac’s first ever twin-turbo engine focused on eliminating turbo lag through a combination of turbocharger design and intake location.

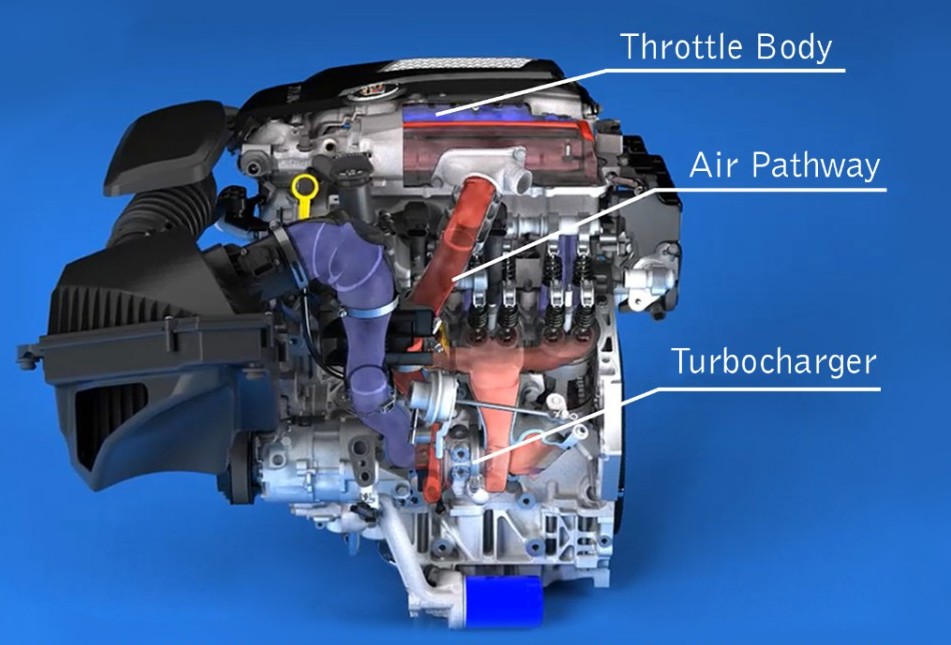

The 420hp, 3.6L V6 engine, available on the 2014 CTS Vsport midsize luxury sedan and XTS Vsport full-size luxury sedan in Canada and the U.S. this fall, utilizes a combination of smaller turbochargers, top-mounted throttle body, and shorter air pathways so unique GM patented the airflow design.

The design eliminates circuitous heat-exchanger tubing and makes the most of engine packaging efficiency to improve torque response time over other air flow designs.

The innovative use of twin turbos allows for faster spooling and immediate power delivery.

Air flow routing volume is reduced by more than 60% when compared with a conventional design that features a chassis-mounted heat exchanger. The water-to-air cooler system achieves more than 80%t cooling efficiency with only about 1 psi (7 kPa) flow restriction at peak power for fast torque production.

“By creating a very short path from the turbos to the throttle body, the compressors are able to draw air directly from the inlet box and send pressurized air through the intercooler immediately,” said Richard Bartlett, Cadillac assistant chief engineer for the 3.6L engine. “This gives the driver a more immediate feeling of power on demand.”

Using two smaller turbochargers rather than a single, larger turbo also helps ensure immediate performance because smaller turbochargers spool up quicker to generate horsepower-building air pressure that is fed into the engine. An integrated charge air cooling system also contributes because the compressors blow through very short pipes up to the intercooler.

The single, centrally located throttle body atop the engine controls the air charge from a pair of turbochargers after the temperature is reduced in the intercooler. This design fosters more immediate torque response and reduces complexity by eliminating the need for a pair of throttle bodies.

Together, smaller turbochargers, top-mounted throttle body and shorter air pathways help sustain peak torque over a broad range – from 1,900 to 5,600 rpm – for power in almost all driving conditions, such as accelerating or overtaking traffic on the highway.

“The Cadillac Twin-Turbo intercooler design builds on our experience with the 6.2L supercharged engine used on the current CTS-V Series,” Bartlett said. “That means more performance for drivers without sacrificing efficiency.”

Leave a Reply