Why Automotive OEMs Need Data-Driven Warranty Models

Share

Share

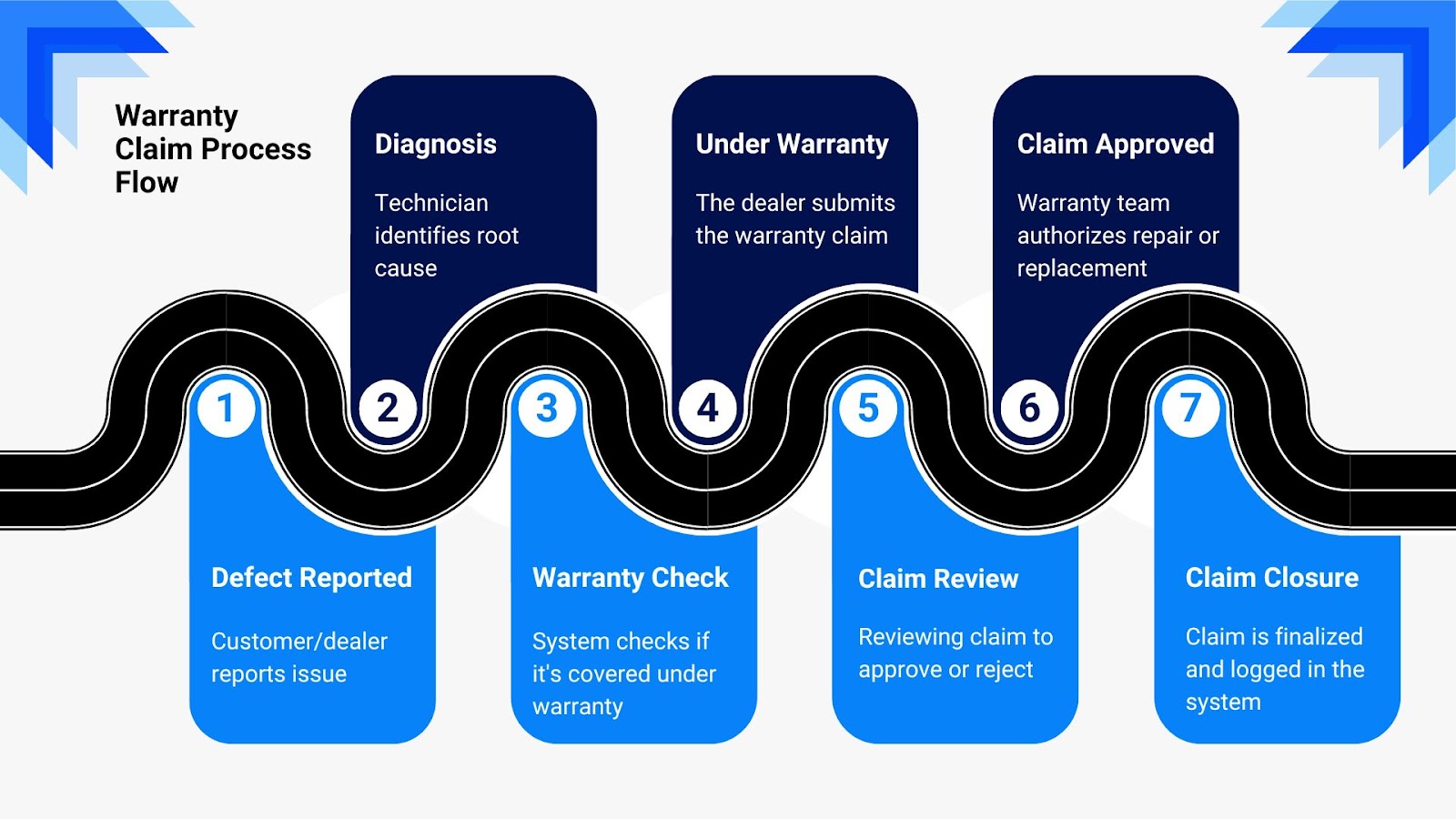

Warranty claim management used to be a laborious procedure that earlier included Excel or paper records that frequently fell short. According to industry estimates, warranty expenses consume $50 billion annually worldwide. The old-school warranty systems are crumbling the automotive OEMs under today’s pressures of smart cars, impatient customers, and thin profit margins.

The way out of this hassle is a data-driven warranty model. An efficient warranty management software with data analytics capabilities can help these automotive OEMs survive in today’s cut-throat market by saving millions, keeping customers loyal, and making more reliable vehicles.

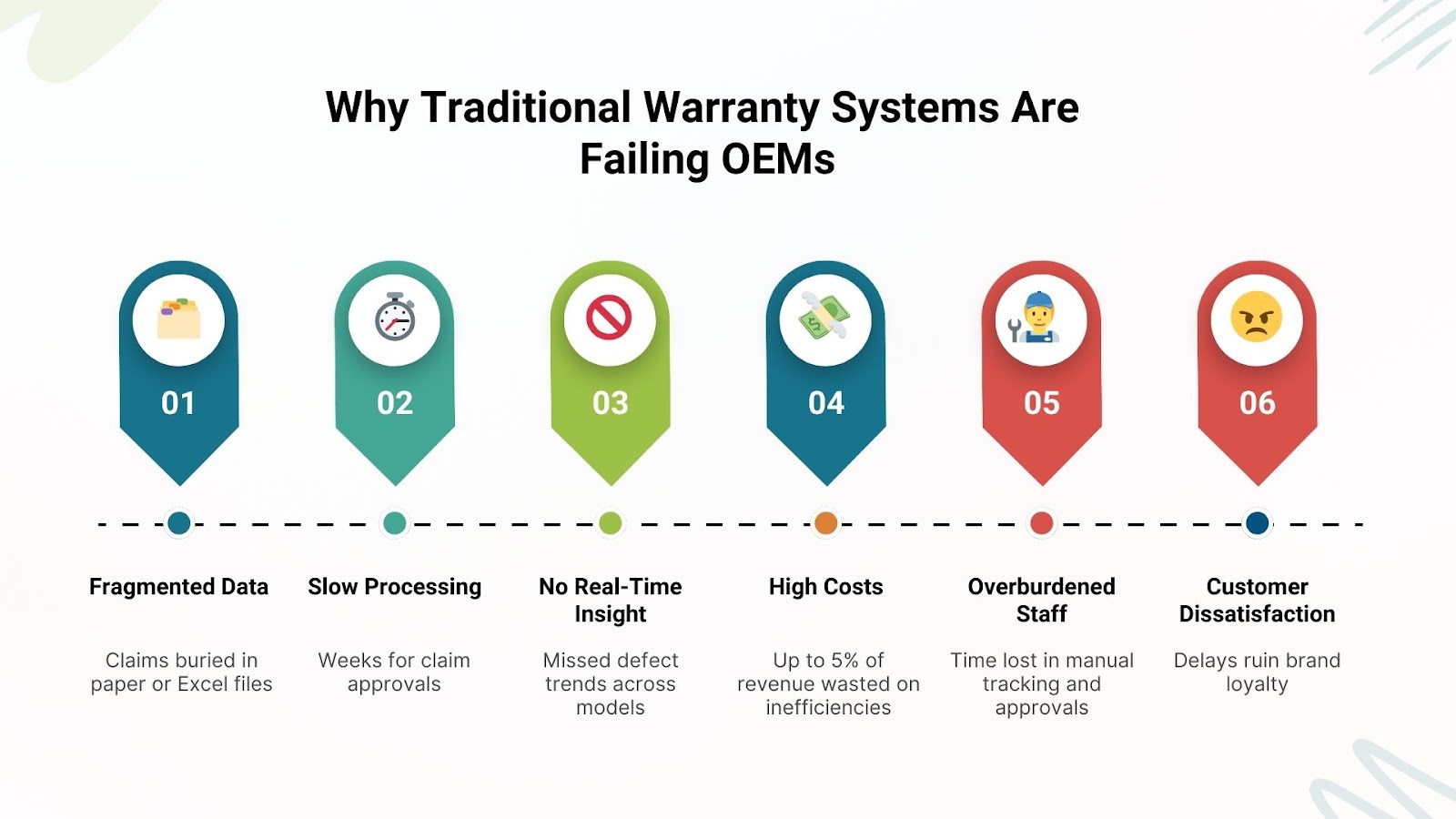

The automotive demands of today are causing conventional warranty methods to collapse. These traditional systems, which rely on data fragmented across paper records or Excel sheets, were developed for times when vehicles were simpler and customers were less demanding.

Traditional warranty systems are outdated, slow, and a disorganized mess. Most of these systems run on manual work that involves dealers mailing in claims, managers grinding through Excel sheets, and technicians waiting long for approvals. Without real-time data, OEMs miss signals like a part failing across a fleet, which leads to delays in claims processing that might last for weeks. And the worst outcome is rising warranty costs. Warranty costs can eat 5% of an OEM’s revenue, as per industry reports, often because of human error or inefficiencies in the data.

The impact of inefficient warranty management is significant. A single overlooked issue may cost an OEM thousands, and inflated warranty costs are a waste of money. According to a 2024 dealer survey, 66% of customers avoid brands that take too long to resolve claims, indicating that customers do not remain loyal to slow service. That’s trust OEMs can’t win back with a discount. In terms of operations, staff are overburdened with paperwork. This time, they could instead spend on enhancing after-sales service. OEMs stuck in this perplexity are losing momentum to their competitors who have invested heavily in data-driven warranty strategies, and the gap is only growing.

These cumbersome, inefficient solutions cost OEMs and their teams valuable customers, time, and money. OEMs must be aware of these limits at the earliest, since the automobile industry is evolving more quickly than ever before. Adopting a data-driven approach is necessary to keep up with current issues in automotive warranty management.

The automobile sector is under strain today due to rising manufacturing costs, intense competition, and consumers who demand flawless vehicles and prompt servicing. These issues are not only hurting OEMs’ bottom lines, but they are also making consumers reconsider remaining loyal to their preferred brands.

Traditional warranty systems were built for a simpler era and can’t handle the complexities of the current aftermarket demands. OEMs’ profitability and brand loyalty are at risk due to sneaky defects that slip through the cracks and slow claims processing.

This makes it essential for automakers to get smart and start using data to tackle this mess. It’s not just a good-to-have option anymore; it has become their lifeline. Here’s why this shift is critical:

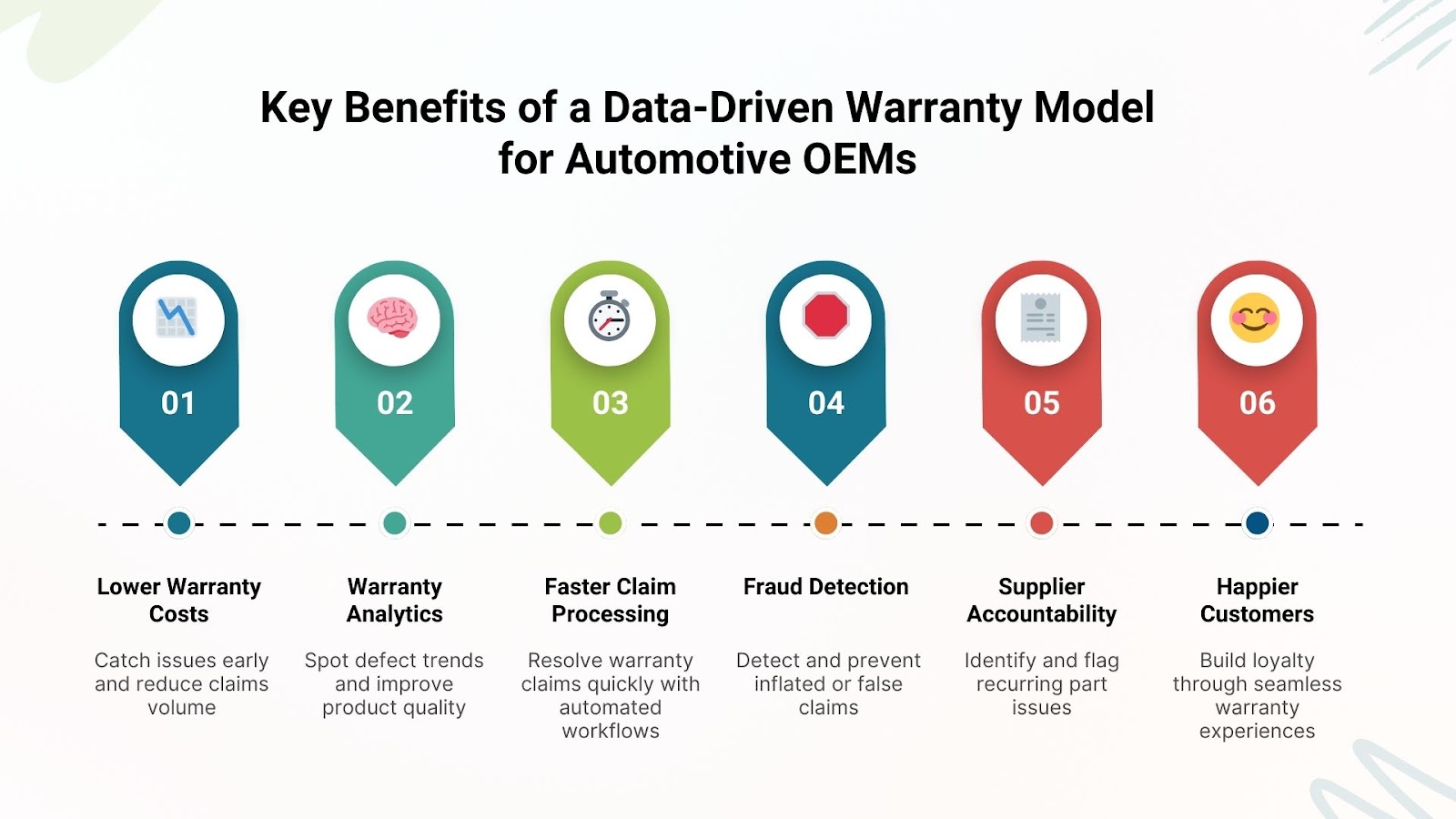

In the aftermarket, OEMs are always under pressure to preserve their profit margins. Their financial stability gets directly impacted by warranty costs, which may take up to 5% of total revenue. These costs must be cut in order to finance innovation and compete on pricing. A single recall can bleed millions off OEMs’ revenue and harm the brand’s identity. Cutting those costs not just saves money but also boosts budgets for innovations, sharper marketing, or expanding the market share.

Keeping customers happy is everything in today’s aftermarket space, where one bad review can go viral. Having slow or complex warranty processing makes the entire process a trouble, pushing customers to your competitors. A 2023 survey observed that 68% of customers admitted they can switch brands if the service is not good. On the other hand, happy customers stay loyal to your brand. They come back for the good service, spread the word, and keep your bottom line healthy. Focus on quick, clear warranty fixes, and you’ll build trust that keeps your brand strong in a crowded market.

Building reliable vehicles is the foundation of an OEM’s reputation. Persistent defects erode customer trust and trigger costly recalls, undermining brand value. Improving product quality through warranty data insights ensures vehicles perform better, last longer, and keep customers coming back. It’s about creating a legacy of dependability that sets an OEM apart in a crowded market.

The evolving automotive industry needs a warranty management system that spots issues before they start, and data-driven warranty models make this possible. Let’s explore how in the next section.

Maintaining an efficient supply chain is imperative for automotive OEMs, but when suppliers mess up, it’s a total disaster. If they send parts that are defective in large volumes, vehicles start breaking down abruptly. That means more trips to the repair shop, frustrated customers, and an inflated warranty budget.

Automobile manufacturers can identify problematic suppliers by sorting through warranty claims. For instance, they may analyze data and determine which suppliers are at fault if a part keeps breaking and vehicles are returning to the workshop frequently. It’s a straightforward, useful method of identifying problems early.

With this approach, suppliers can be held accountable for poor parts, which encourages them to step up. OEMs can analyze the data to evaluate if the parts are of good quality and whether suppliers address quality issues actively.

Then there are instances of warranty fraud, which is just the worst thing to tackle. Some dealers may overestimate repair costs, like every repair is a million-dollar job, and a few customers might make false claims about how their vehicle went out of order. A 2024 report states that these frauds eat up 10-15% of OEMs’ warranty costs annually, which is a significant amount of money going down the drain.

A data-driven warranty system helps OEMs reduce the risk of such fraud by analyzing patterns in vehicle data to identify inconsistencies in claim patterns. The goal of cracking down on this is to minimize such fraud while also ensuring that the valid claims don’t go unnoticed.

Automakers might be able to get ahead of the curve and stop rushing to solve every minor issue if they would just allow data to drive them.

Make sure to explore this related guide:

A Complete Guide to Warranty Management Software

Warranty management software driven by data is the game-changer here. This software tackles the issues OEMs face every day by eliminating laborious work out of claims processing, and churning out insights that cut through the fog. It provides functionalities like automated workflows to speed up approvals, dashboards for tracking claims on the go, and predictive tools to head off disasters.

An efficient warranty management software can help OEMs slash processing time by 40%, freeing their teams to tackle bigger challenges. Beyond just improving processing speed, these platforms grow with your business, generate instant reports for making informed decisions, and stop recalls with predictive smarts. For automotive OEMs, these data-driven solutions are the backbone of tomorrow’s automotive after-sales service.

Switching to a data-driven warranty model might initially seem a hassle, but it’s worth it. Here’s a guide to help OEMs get it done:

Assess Current Warranty Processes

Evaluate your current warranty management setup. Are claims stuck in paper piles? Are you missing patterns because the data is scattered? Know your weak spots first.

Invest in a Data-Driven Warranty Management Software

Adopt a warranty management platform with robust analytics and maintenance functionalities. Keeping your business goals in mind, draw fair comparisons between industry-available offerings and choose one that suits your objectives best.

Integrate IoT and Telematics

Use vehicle sensors to pull real-time data. This fuels predictive maintenance, cutting unexpected breakdowns.

Train Teams on Data Interpretation

Get your crew up to speed on warranty management software. Efficient training ensures your teams have knowledge of the latest updates in the software and how things work.

Track KPIs and Warranty Analytics

Monitor customer feedback, warranty costs, and claim resolution time. Checking in frequently helps you stay on track.

To smooth out the implementation of warranty management software, start at a small scale first. With this method, managing vehicle warranties is easier and less stressful.

The consequences of automotive OEMs sticking to the old methods of warranty management are severe, including rising costs, unhappy customers, and lost opportunities for product excellence. Data-driven automotive warranty management overcomes these hassles. With its analytics and automation, warranty management software opens the door to quality, loyalty, and savings.

The route to futuristic warranty management is simple: examine your existing configuration, select the appropriate software, and process warranty claims efficiently with data-driven insights. You deserve better for your business and your customers.

Leave a Reply