How Injection Molding Works and Why It Matters in the Automotive Industry

Share

Share

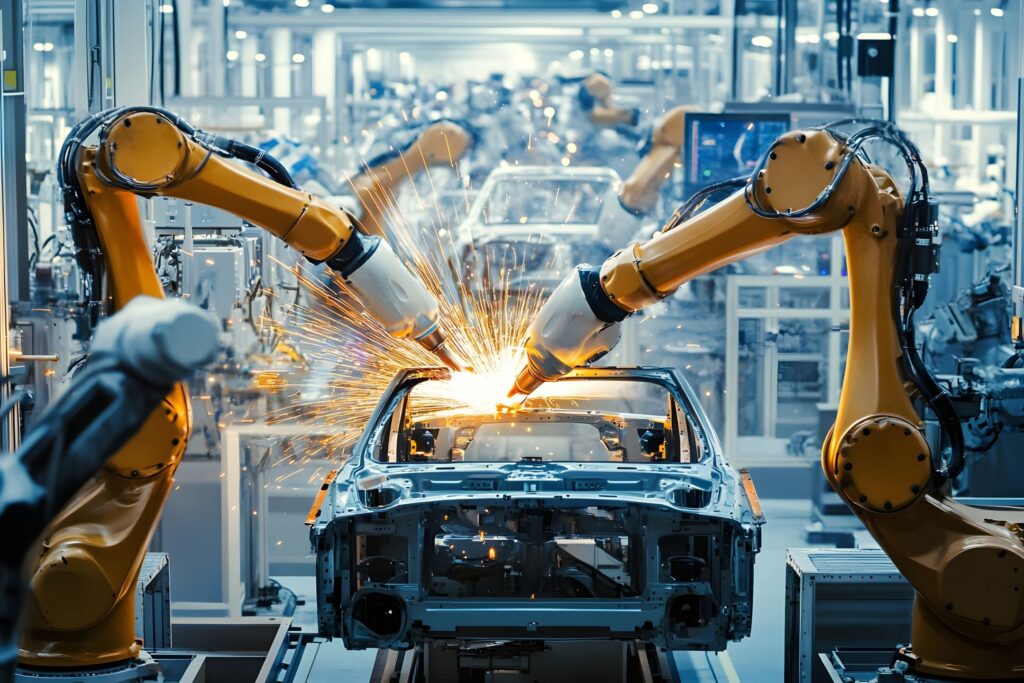

The automotive industry relies on precision, efficiency, and cost-effectiveness in manufacturing. One of the most critical processes enabling these requirements is injection molding. This method allows for the mass production of high-quality, durable, and complex parts with minimal waste. Understanding how injection molding works and its significance in automotive manufacturing can provide insights into why it remains indispensable.

Read on to learn more.

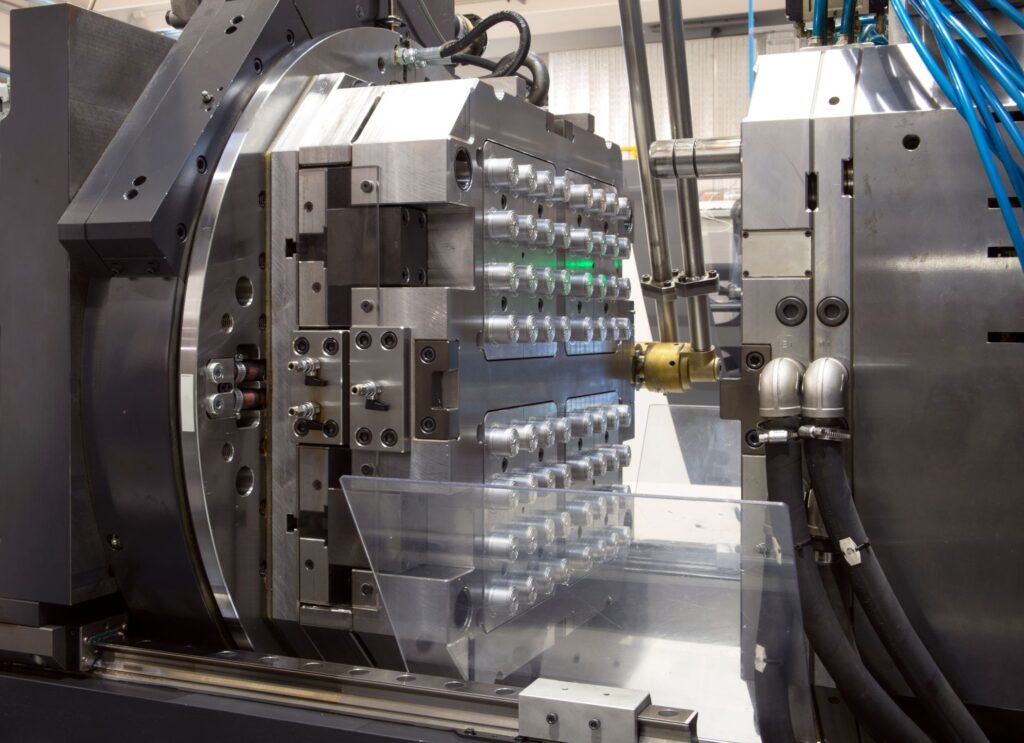

Injection molding is a high-precision manufacturing process that transforms raw plastic pellets into complex automotive components through controlled thermal and mechanical action. The pellets are melted in a precisely heated barrel; then, a reciprocating screw injects the molten polymer at pressures up to 30,000 psi into temperature-regulated steel molds. After a calculated cooling period, hydraulic ejector pins release the dimensionally stable part, completing cycles that can take as little as 15-30 seconds while maintaining tolerances within ±0.005 inches for critical automotive applications.

Furthermore, automotive injection molding delivers precision-engineered components with complex geometries and micron-level accuracy, essential for modern vehicle manufacturing. Advanced processes like gas-assisted injection molding can create hollow structures with perfect wall thickness for lightweight yet robust bumpers, while overmolding combines multiple injection molding materials in a single cycle to produce soft-grip interior trim with integrated mounting features. These technologies enable seamless integration of mechanical fasteners, living hinges, and Class-A surfaces in components ranging from intricate HVAC vents to structural door panels.

However, for those wanting to learn more about automotive injection molding and how it works, consulting professionals would be an excellent start.

Injection molding revolutionizes the auto manufacturing industry in several ways. Below are the key advantages of injection molding in auto manufacturing:

Injection molding enables automakers to produce large quantities of identical parts with minimal variation, ensuring vehicle uniformity. Once the mold is precision-engineered and validated, the process allows for fast, continuous production cycles. This efficiency is vital for meeting tight production schedules and maintaining strict and consistent quality standards in high-demand automotive markets. The repeatability of the injection process can reduce defects, lower the cost of production, and support just-in-time manufacturing, making it indispensable for mass vehicle production.

Injection molding’s material versatility allows automakers to tailor components for specific functions—rigid plastics for structural parts, flexible elastomers for seals, and heat-resistant composites for engine components. Advanced polymers like ABS, polypropylene, and nylon can be precisely selected to meet strength, weight, and durability requirements, ensuring optimal performance across diverse automotive applications. Experienced manufacturers like Advanced Plastiform, Inc can assist with material selection and production optimization.

Injection molding is inherently efficient, as nearly all material is used in the final part, minimizing scrap. Runners and sprues can often be reground and reused, further cutting waste. Multi-cavity injection molds also allow the simultaneous production of several parts, maximizing output while reducing energy and labor costs per unit. These are key advantages for sustainable, cost-effective automotive manufacturing.

The automotive industry’s push for fuel efficiency has made lightweight plastics essential. Injection-molded components can weigh approximately 50-70% less than comparable metal parts while maintaining structural integrity. This weight reduction can improve miles per gallon (MPG) ratings, helping automakers meet stringent emissions standards. Advanced engineering plastic materials like carbon-fiber-reinforced polymers now rival metals in strength-to-weight ratios, enabling safer, more efficient vehicles without performance compromises.

Injection molding serves as the backbone of modern automotive manufacturing. The following are some complex molding applications in the automotive sector:

Injection molding enables the production process of automotive interiors that blend form and function seamlessly. The process allows for intricate detailing, soft-touch surfaces, and custom textures that elevate cabin aesthetics while integrating practical features like hidden storage and ergonomic controls. Molding complex geometries as single pieces can help reduce assembly steps while achieving premium fit-and-finish standards that consumers expect in modern vehicles.

Injection molding projects transform automotive exteriors by producing electronic components that combine durability with mold design flexibility. The process can create bumpers with energy-absorbing structures, grilles with precise aerodynamic profiles, and mirror housings that withstand road debris. UV-stabilized polymers and impact-modified blends can maintain structural integrity through extreme temperatures, salt exposure, and collisions while enabling sleek, modern vehicle styling that is impossible with traditional materials.

Under-the-hood components face extreme operating conditions that demand advanced material solutions. Injection molding utilizes high-performance polymers like glass-filled nylon, PPS, and PEEK that resist temperatures exceeding 200°C while maintaining structural stability. These engineered plastic products can prevent degradation from oil, coolant, and vibration, ensuring reliable protection for sensitive engine components and electrical systems throughout the vehicle’s lifespan.

The future of automotive injection molding is being revolutionized by cutting-edge technologies. Bio-composites from renewable sources can reduce environmental impact, while 3D printing molds can enable rapid prototyping and complex geometries. Industry 4.0 integration can also bring AI-driven process optimization and real-time quality monitoring, allowing unprecedented customization with shorter production times. This can transform how vehicles are designed and manufactured for tomorrow’s mobility solutions.

Injection molding is a cornerstone of automotive manufacturing, offering unmatched precision, efficiency, and versatility. Its ability to produce lightweight, durable, and cost-effective electrical components makes it indispensable in vehicle production. As technology progresses, automotive injection molding will continue to play a pivotal role in meeting industry demands for innovation and sustainability.

By keeping the information mentioned above in mind, automakers can maintain competitive advantages while delivering high-quality vehicles to consumers worldwide.

Leave a Reply