How Industrial 3D Printing is Redefining Automotive Part Production

Share

Share

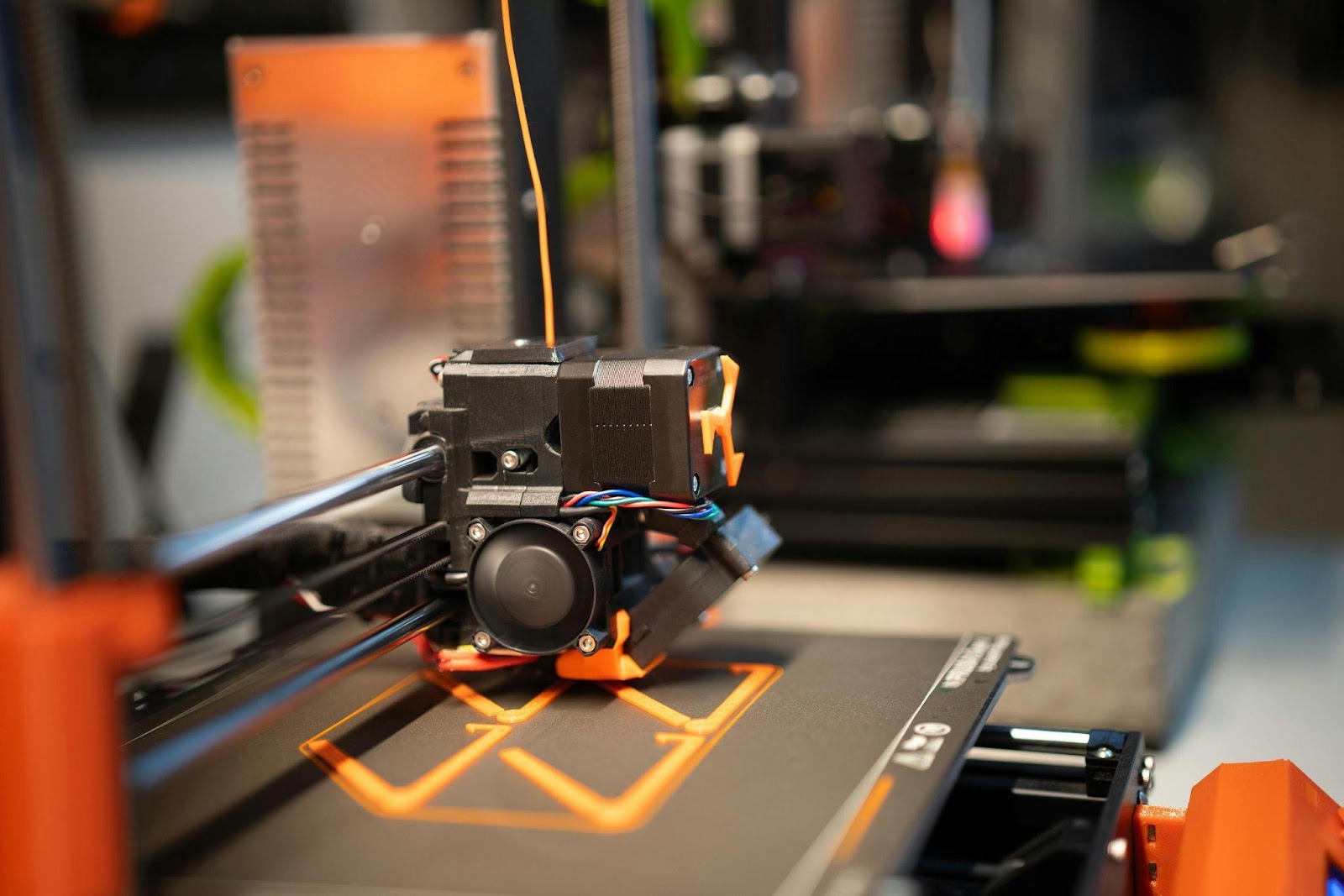

It wasn’t long ago that 3D printing felt like a niche tool—ideal for hobbyists, engineers tinkering with plastic prototypes, or tech expos showing off futuristic concepts. But the automotive industry has shifted that narrative. Today, 3D printing is no longer just an experimental sidekick—it’s stepping into the driver’s seat of automotive part production.

Across global manufacturing floors, an industrial-grade 3D printer for the automotive industry is enabling faster development cycles, leaner supply chains, and custom part solutions that were previously unthinkable using traditional methods. From creating lightweight structures in electric vehicles (EVs) to printing titanium brake calipers that outperform their forged counterparts, additive manufacturing is altering how we approach design, production, and innovation itself.

This guide explores the multi-faceted transformation underway—examining core processes, essential materials, emerging technologies, real-world use cases, and the future outlook for industrial 3D printing in the automotive world.

Industrial 3D printing, also known as additive manufacturing (AM), is the process of building objects layer by layer using digital design files and specialized materials such as high-performance thermoplastics, metals, or resins. Unlike desktop 3D printing, which is mostly used for prototyping or small-scale personal projects, industrial 3D printing operates at a significantly higher scale, precision, and material complexity, meeting the rigorous demands of manufacturing environments—especially in the automotive sector.

The race toward lighter, smarter, and more efficient vehicles is intensifying—and traditional manufacturing isn’t always fast or flexible enough to keep up. As automakers face increased pressure to reduce emissions, respond to supply chain disruptions, and offer personalized vehicles, industrial 3D printing is emerging as a strategic enabler.

Additive manufacturing allows engineers to rethink how parts are designed and produced. No longer constrained by molds or subtractive limitations, designers can incorporate organic geometries, optimize internal structures, and merge multiple components into a single print—cutting both weight and complexity.

At its core, the industrial 3D printing workflow in automotive follows a structured yet flexible pipeline—from the earliest design phase to rigorous quality checks. Unlike linear manufacturing processes, 3D printing offers iterative flexibility, allowing engineers to adapt designs quickly without major cost implications.

This digital-to-physical pipeline not only enhances speed but also unlocks a level of production flexibility that traditional methods simply can’t match—especially for low- to medium-volume parts.

Different applications in automotive demand different additive manufacturing technologies. While prototyping often relies on polymer-based printing methods, end-use part production leans heavily on metal AM or high-performance polymers with engineering-grade tolerances.

Below is a breakdown of the main technologies currently shaping automotive 3D printing.

FDM works by extruding thermoplastic filaments layer by layer. It’s widely used for functional prototypes, jigs, and fixtures.

SLS uses a laser to fuse powdered polymers. It produces strong, complex parts without the need for support structures.

SLA employs a UV laser to cure photopolymer resin. Known for high-resolution prints with excellent surface finish.

DMLS uses a high-powered laser to sinter metal powders, enabling the production of fully dense, high-strength metal parts.

In binder jetting, a liquid binder is deposited onto a powder bed to form layers, followed by sintering.

EBM uses an electron beam in a vacuum to melt metal powders. Ideal for parts that require high strength and complex geometry.

MJF uses a fusing agent and detailing agent applied by inkjet heads and then fused by heating elements.

As industrial 3D printing transitions from the R&D lab to full-scale production, the automotive parts being printed have expanded well beyond prototypes. Today’s additive manufacturing capabilities allow for both functional components and structural parts to be printed with production-grade materials and precision.

Manufacturers are strategically choosing which parts to print based on factors like design complexity, part size, customization needs, and cost. Especially in motorsports, electric vehicles, and luxury models—where performance and design innovation are paramount—3D printing is unlocking new forms of value.

The diversity of these parts signals a broader transformation—not just in what gets printed, but in how engineers design parts when freed from the constraints of traditional subtractive methods.

The choice of material can make or break a part’s performance in an automotive setting. Whether it’s enduring the searing heat of an engine bay or the repetitive stress of daily use, each material used in automotive additive manufacturing brings its own advantages, limitations, and ideal applications.

These polymers withstand extreme temperatures, chemicals, and mechanical loads. Common in under-the-hood applications and electrical insulators.

Strong, flexible, and impact-resistant, nylon is ideal for parts requiring high durability and minor flexibility.

These composites combine thermoplastics with chopped carbon fibers, enhancing stiffness and strength while keeping weight low.

Aluminum AM parts offer an excellent balance of strength and weight. Used for both performance and structural applications.

Titanium is corrosion-resistant, extremely strong, and lightweight—making it ideal for motorsport and high-performance applications.

Stainless steel provides excellent durability and resistance to wear and corrosion. Ideal for tooling and components exposed to high stress.

Used for creating jigs, fixtures, and molds with high detail and dimensional accuracy.

Each material’s adoption is influenced by factors such as cost per kilogram, post-processing requirements, certification standards, and part lifecycle expectations. The growing portfolio of materials is one of the reasons 3D printing is rapidly expanding from niche to mainstream manufacturing.

From streamlined development to long-term sustainability benefits, additive manufacturing introduces several layers of advantage. For automakers looking to remain competitive in a shifting landscape defined by EV innovation, global supply chain disruptions, and stricter environmental regulations, these advantages are no longer optional—they’re essential.

In essence, industrial 3D printing brings speed, agility, and innovation to an industry traditionally bound by volume economics and rigid production lines.

To understand 3D printing’s growing relevance, it’s helpful to contrast it with long-established methods. While traditional manufacturing excels in high-volume, low-variation production, 3D printing wins when complexity, customization, and agility are needed.

| Process | Strengths | Weaknesses |

| Injection molding | Excellent for high-volume runs, consistent quality | High tooling cost, limited to simpler shapes |

| CNC machining | Precision and material versatility | High waste, slower setup for new parts |

| Die casting | Good for complex metal parts | Costly dies, less flexible to design change |

| Sheet metal forming | Great for flat or simple geometries | Difficult for intricate or hollow forms |

| 3D printing | Design freedom, rapid iteration, on-demand production | Slower for mass production, limited material throughput |

Ultimately, hybrid workflows—combining 3D printing with CNC or casting—are emerging as the best of both worlds, especially for functional prototypes or low-to-mid volume specialized parts.

In automotive manufacturing, the line between prototyping and production is increasingly blurred thanks to 3D printing. Once reserved for early-stage design models, additive manufacturing is now being leveraged across the entire product lifecycle—from concept validation to functional, road-ready components.

What’s emerging is a dual-purpose value—accelerating development while simultaneously enabling smarter production. The same printer used to build a prototype can now produce end-use parts, eliminating the gap between design and delivery.

Automotive parts must perform under strict mechanical, thermal, and environmental conditions. As such, 3D printed components are subject to rigorous testing to ensure compliance with industry standards.

These processes ensure that parts produced by additive manufacturing can match or exceed the reliability of traditionally produced components—crucial in both safety-critical systems and daily operational use.

The future of automotive manufacturing is increasingly digital, decentralized, and data-driven—and 3D printing is at the center of this transformation. As machines become faster, materials more diverse, and design tools smarter, additive manufacturing will move from a niche solution to a foundational capability.

The industry is moving beyond prototypes—it’s printing possibilities.

The story of automotive manufacturing is being rewritten—not with a wrench, but with a printhead. Industrial 3D printing is no longer on the fringe. It’s at the heart of a movement toward leaner factories, smarter designs, and supply chains that think in code, not crates.

This guide has shown how additive manufacturing transforms every phase of production—from the drawing board to the road. It’s enabling automakers to reimagine parts, processes, and even business models. While it won’t replace every bolt and bracket made the traditional way, it’s clear that 3D printing is no longer the future of automotive—it’s the now.

As machines get faster, materials smarter, and engineers bolder, the industry stands on the edge of a new design frontier—one where metal and polymer flow not from a mold, but from an idea instantly made real.

Leave a Reply