Timing Belt in Oil: The Next Frontier in Engine Technology is Here

Share

Share

As the automotive industry pushes the boundaries of internal combustion engine performance—demanding more power, better fuel efficiency, and lower emissions—manufacturers continue to seek cutting-edge solutions. One such innovation is Dayco’s timing belt in oil (TBIO), a breakthrough belt system that gave automakers the power to transform the way engines are built and will ultimately impact how they are serviced.

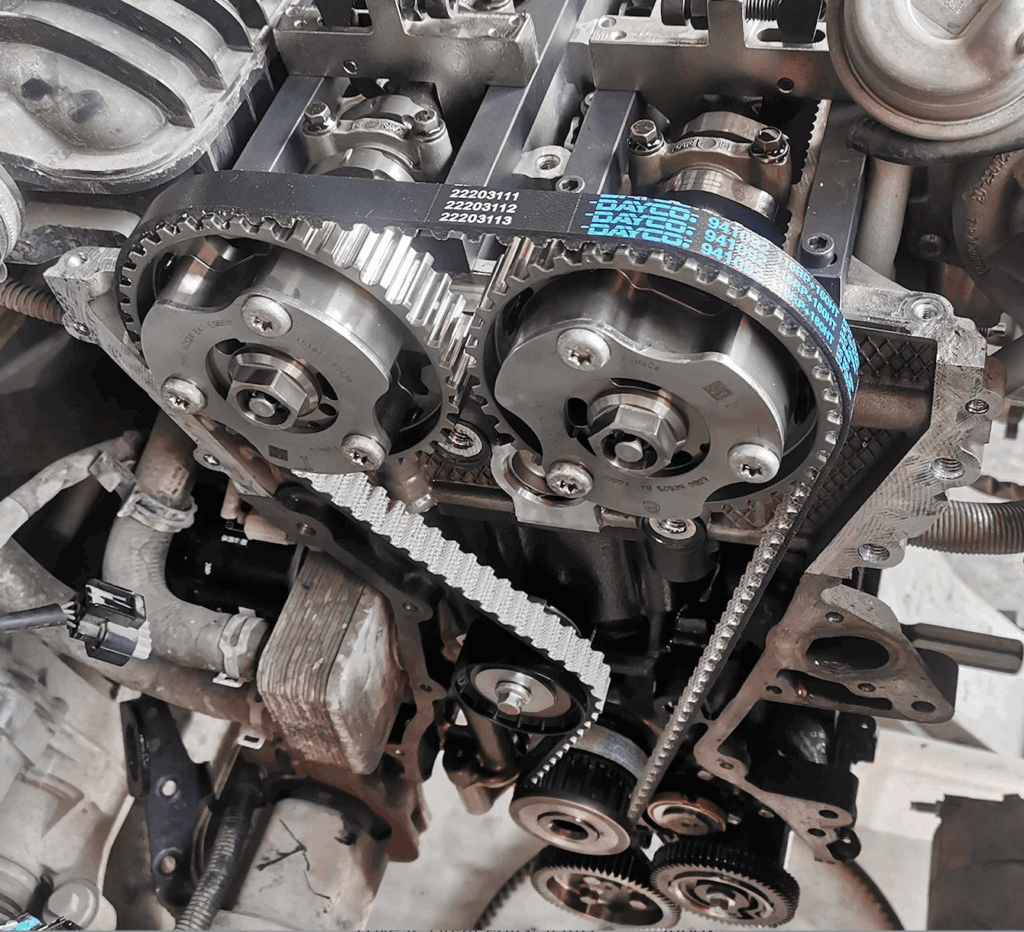

Originally developed to meet the growing needs of OEMs, timing belt in oil was first introduced on the Ford ‘Lynx’ engine and later adopted in models like the Ford 1.0-liter EcoBoost, Stellantis 1.2-liter PureTech, and Ford 2.0-liter EcoBlue. Today, it’s gaining traction across multiple automakers globally, and aftermarket demand is rising fast.

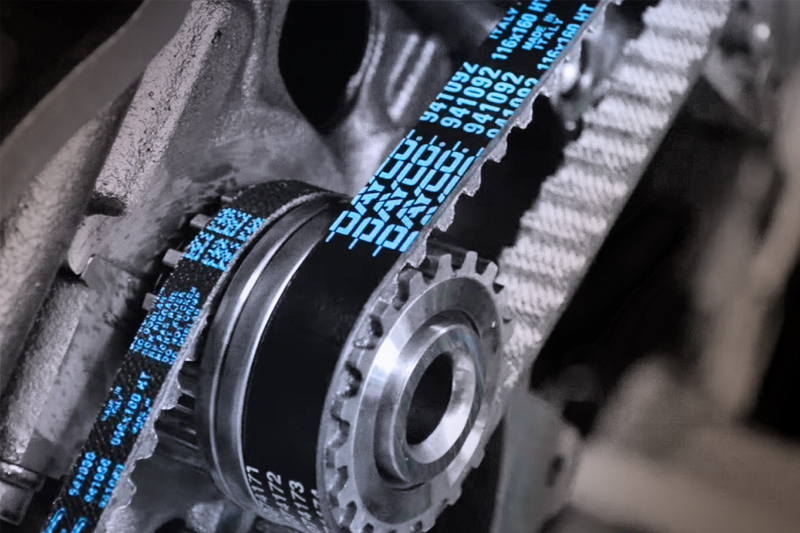

Unlike traditional dry timing belts, a timing belt in oil operates submerged in motor oil on the wet side of the engine, much like a timing chain. This configuration allows for:

Constructed from oil-resistant materials and reinforced with high-strength cords, timing belt in oil was engineered by Dayco to combine the best characteristics of both belts and chains—offering performance, reliability and efficiency in a compact form.

With millions of vehicles now outfitted with timing belts in oil and many reaching their recommended OE service intervals, a new opportunity for jobbers, distributors and repair shops is emerging.

Given how new the technology is, many motorists aren’t aware that their vehicle even contains this component—especially in vehicles that appear to have a “timing chain” setup. This knowledge gap presents a massive growth avenue for educating motorists and offering timely replacements with OEM-grade parts.

As the original OE supplier and first to market, Dayco now offers timing belt in oil for aftermarket applications, starting with more than 2 million Ford and Lincoln models. Additional part numbers are expected and will align with the growing number of TBIO-equipped vehicles on the road.

Built for extreme performance and reliability, Dayco timing belt in oil delivers exceptional strength, stiffness and durability for the harshest engine environments. It maintains consistent timing and long-term performance while reducing noise, vibration and friction for a quieter, more refined driving experience.

The use of timing belts in oil is growing as OEMs seek to reduce engine weight, improve efficiency, and cut noise and vibration levels. By integrating belt-in-oil systems, they’re able to downsize engines without sacrificing performance—a trend that aligns with global emissions targets and consumer preferences for smoother rides.

With millions of vehicles already on the road using TBIO systems and more models adopting the technology each year, repair shops, jobbers and distributors who prepare now by stocking OE-quality TBIO and educating consumers will be best positioned to capitalize on this expanding segment.

What I gathered is that this timing belt in oil is not in the interest of the end consumer, these are for the benefit of the manufacturer who has to meet certain emission and fuel efficiency norms on the whole across their product portfolio. So they look for avenues to extract the tiniest of efficiency gains from wherever they can and reliability be damned. The belt in oil has 30% less frictional losses than a timing chain system for a net 1% fuel efficiency gain.

But they don’t seem to be very reliable going by the information available on the internet. The most common issue is the belt gradually wearing off in the oil and the belt dust settling in the sump and then blocking oil pump intake. There’s a new belt of another chemistry which is supposedly better. But ironically the manufacturer recommends reduced replacement intervals with this new belt.

Leave a Reply